Steel Panel Formwork

The Steel Panel Formwork System, an advanced solution designed for versatility and efficiency in construction, provides a robust framework for building various structural elements. This system is particularly suited for erecting shear walls, core walls, and columns across a range of heights, without requiring pre-assembly.

Adopting the Steel Universal Panel System in construction projects leads to significant efficiency gains through its easy assembly, high durability, and flexible configuration options. The system’s robust design minimizes the need for constant maintenance, while its versatile panel dimensions facilitate rapid adjustments on-site, enhancing overall project timelines and reducing labor costs.

The Steel Universal Panel System is a comprehensive solution that caters to the dynamic needs of modern construction environments. It stands out by providing a practical, durable, and adaptable option for developers and contractors aiming to improve their operational efficiency and structural integrity in building projects.

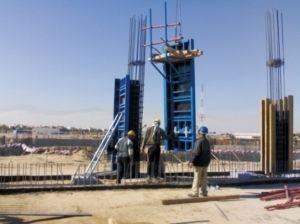

120 Steel Panel Formwork Project

Why Rapid?

•Versatility: Suits a broad range of projects, from high-rises to bridges. • Quality Finishes: Guarantees superior concrete surface quality.

• Auto-Climbing Technology: Offers safer, crane-less high-rise construction.

• Economic Efficiency: Balances cost-effectiveness with safety.

• Robust Load Capacity: Ensures reliability under high concrete pressures.

•Custom Solutions: Adapts to specific project needs with adjustable systems.

• Expert Support: Provides experienced guidance and service.

• Standards Compliance: Meets international safety and quality standards.

• Sustainability: Emphasizes reusable materials for less environmental impact.

Dimensions and Configurations: The panels are available in three primary heights: 3.30m, 2.70m, and 1.20m, and widths ranging from 0.30m to 2.4m at increments of either 0.05m or 0.15m. This modular approach ensures flexibility and adaptability for different construction needs.

Construction and Material: Each panel features a cold roll-formed steel frame with a unique internal edge shaping that supports the use of an alignment couple for precise positioning. The vertical edge profiles are equipped with strategically placed holes that facilitate accurate alignment using simple tools like crowbars.

Plywood Integration: The structural integrity is further enhanced by an 18mm thick, 7-fold glued plywood sheet, supported by eight to ten equally spaced intermediate bars. This setup not only provides stability but also offers multiple attachment points for various system accessories.

Durability and Load Capacity: The entire frame of the Steel Universal Panel System is painted to resist environmental stress and corrosion. A panel depth of 12cm allows for a load-bearing capacity of 70 KN/m2, making it ideal for single-story constructions where the rate of concrete placement and pressure are not critical factors.

Versatile Installation Options: Panels can be oriented horizontally or vertically, and their unique design permits staggered arrangements without being confined to dimension modules. This flexibility is critical for optimizing construction processes and adapting to project-specific requirements.

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Rapid represent the safety and qualified 120 Steel Panel Formwork via our construction projects.

Feel the Quality via our products. We improve them always.