Cuplock Scaffolding

Reliable cuplock scaffolding manufacturer in China, we can custom any steel cuplock scaffolding system based on your project needs. Our cuplock system is very strong, high-load capacity, and fast to connect with the cup-lock design. Q355 raw material, powder coated, painting, and hot dip galvanized surface treatment. Suitable for construction, shoring support, industrial access and heavy-duty projects. We offer stable quality, full engineering service, 3D design and fast delivery to support your work.

Cuplock Scaffolding Manufacturer in China

Rapid is one of the leading cuplock scaffolding manufacturers and suppliers in China. Their cuplock scaffolding system is developed and produced with highest standards to make sure it meets the requirements of any user. Its simple-yet-effective design ensures easy installation and maximum structural stability, while proven components ensure quick locking into place without compromising safety. With cuplock scaffolding from Rapid, you can be assured of quality performance and durable system that can last a long time. So if you have any requirement for cuplock scaffolding, don’t hesitate to get in touch with them!

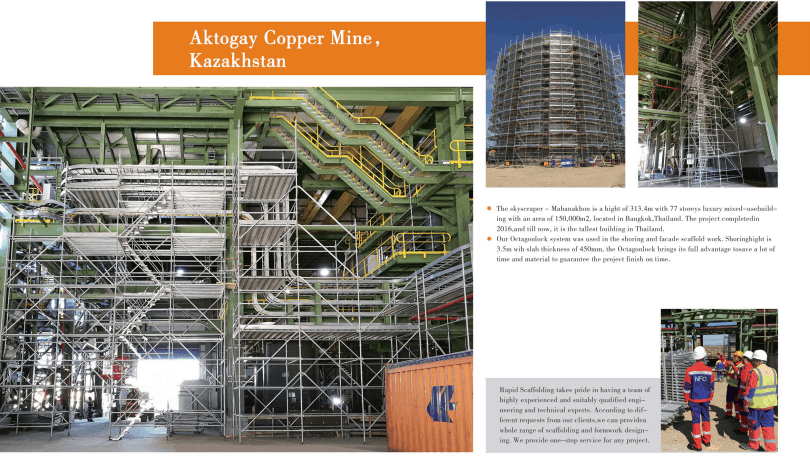

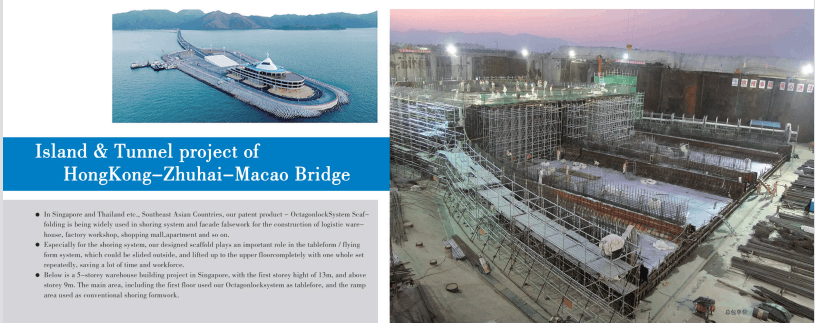

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Rapid scaffolding has rich experience and advanced automatic equipment, which can provide scaffolding customized production to meet different needs.

Rapid represent the safety and qualified scaffolding via our construction projects.

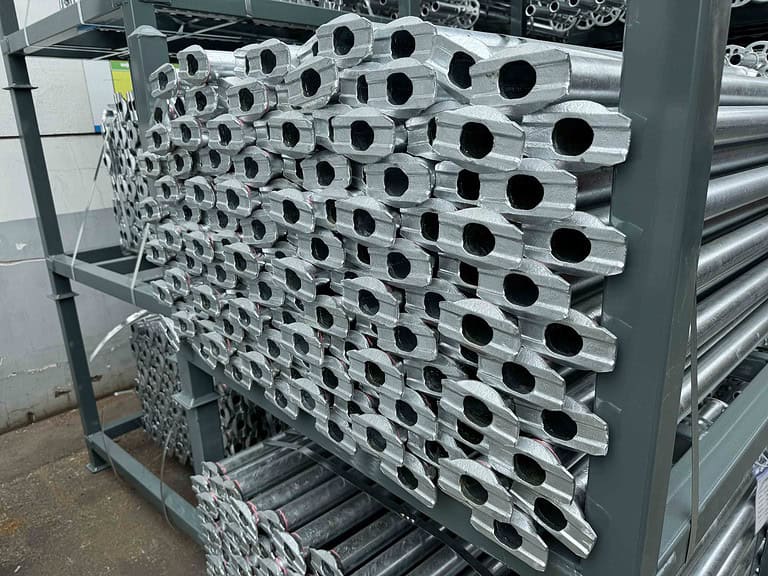

Feel the Quality via our products. We improve them always.

Rapid Cuplock Scaffolding Video

Why Choose Rapid?

• High quality scaffolding at competitive price

• Customized standards to meet the specific needs of any work site

• Commitment to safety and durability in all products

• Innovation in design for a better customer experience

• Scaffold services available 24 hours/day, 7 days a week

• Accreditation from EN10901 and ISO3834 for quality assurance

• Certified as work-safe and compliant with all scaffold regulations

• Wide variety of scaffolds available in different sizes to suit all needs

• Comprehensive training provided on how to use the scaffolds safely

Cuplock Scaffold Specifications:

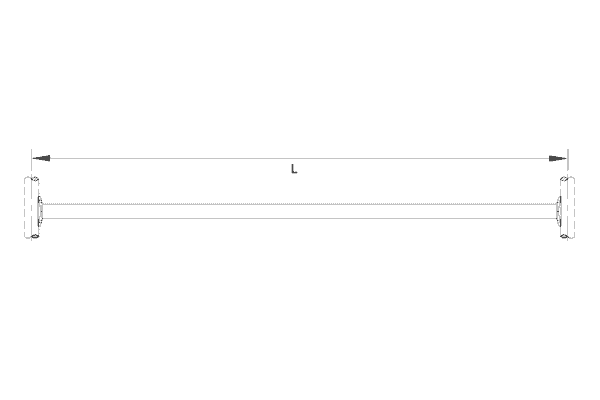

Cuplock Standard

This Cuplock Standard is perfect for all your construction needs! Its tube diameter of 48.3mm and thickness of 3.2mm make it a sturdy, reliable option that you can count on. And its galvanized surface treatment will help keep it looking great for years to come!

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q345, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLS500 | 1 Cup standard w/spigot 1′-8″ | 19.69 | 0.5 |

| CLS1000 | 2 Cup standard w/spigot 3′-3″ | 39.37 | 1.0 |

| CLS1500 | 3 Cup standard w/spigot 4′-11″ | 59.06 | 1.5 |

| CLS2000 | 4 Cup standard w/spigot 6′-6″ | 78.74 | 2.0 |

| CLS2500 | 5 Cup standard w/spigot 8′-2″ | 98.43 | 2.5 |

| CLS3000 | 6 Cup standard w/spigot 9′-10″ | 118.11 | 3.0 |

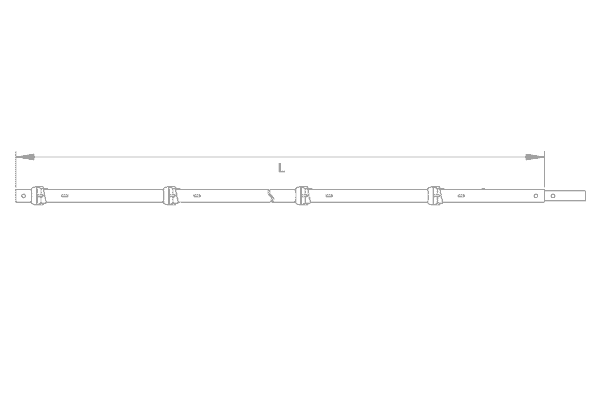

Cuplock Ledger

We have created the world’s strongest and most durable ledger! Our Jumply/Cuplock Ledger is perfect for keeping your books in order. With a diameter of 48.3mm and thickness of 3.2mm, it can withstand anything you throw at it! The surface treatment is hot dip galvanized, ensuring that it will last long and look good doing it!

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q345, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLL787 | 2′-7″ Ledger | 31 | 0.787 |

| CLL914 | 3′ Ledger | 36 | 0.914 |

| CLL1066 | 3′-6″ Ledger | 42 | 1.066 |

| CLL1219 | 4′ Ledger | 48 | 1.219 |

| CLL1524 | 5′ Ledger | 60 | 1.524 |

| CLL1828 | 6′ Ledger | 72 | 1.828 |

| CLL2133 | 7′ Ledger | 84 | 2.133 |

| CLL2438 | 8′ Ledger | 96 | 2.438 |

| CLL2743 | 9′ Ledger | 108 | 2.743 |

| CLL3048 | 10′ Ledger | 120 | 3.048 |

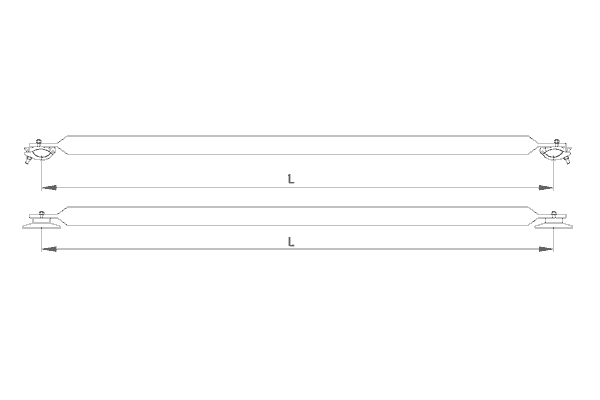

Cuplock Diagonal Brace

With a diameter of 48.3mm and a thickness of 3.2mm, this steel tube is perfect for creating sturdy ledgers. It’s made from Q345 steel and has a hot dip galvanized finish to protect it from the elements.

Tube diameter: 48.3mm, thickness: 2.5mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Width | Length | |||

| code | description | Inches | Meters | Inches | Meters |

| CLDB2342 | 4′ Diagonal Brace | 48 | 1.219 | 78.74 | 2 |

| CLDB2514 | 5′ Diagonal Brace | 60 | 1.524 | 78.74 | 2 |

| CLDB2693 | 5′-11″ Diagonal Brace | 71 | 1.803 | 78.74 | 2 |

| CLDB2924 | 7′ Diagonal Brace | 84 | 2.133 | 78.74 | 2 |

| CLDB3153 | 8′ Diagonal Brace | 96 | 2.438 | 78.74 | 2 |

| CLDB3193 | 8′-2″ Diagonal Brace | 98 | 2.489 | 78.74 | 2 |

| CLDB3394 | 9′ Diagonal Brace | 108 | 2.743 | 78.74 | 2 |

| CLDB3645 | 10′ Diagonal Brace | 120 | 3.048 | 78.74 | 2 |

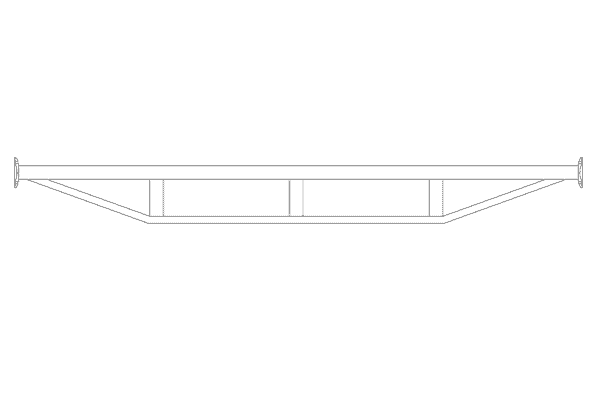

Cuplock Truss

Introducing the newest member of the Jumply/Cuplock family – the Cuplock Truss! This truss is made with a 48.3mm diameter tube and a thickness of 3.2mm, making it strong and durable enough to support any load. It’s also hot dip galvanized for a long-lasting finish.

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLT2133 | 7′ Truss | 84 | 2.133 |

| CLT2438 | 8′ Truss | 96 | 2.438 |

| CLT2743 | 9′ Truss | 108 | 2.743 |

| CLT3048 | 10′ Truss | 120 | 3.048 |

| CLT3658 | 12′ Truss | 144 | 3.658 |

| CLT4267 | 14′ Truss | 168 | 4.267 |

| CLT4877 | 16′ Truss | 192 | 4.877 |

| CLT5486 | 18′ Truss | 216 | 5.486 |

| CLT6096 | 20′ Truss | 240 | 6.096 |

| CLT6401 | 21′ Truss | 252 | 6.401 |

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLBB360 | One Board | 11.4 | 0.29 |

| CLBB390 | Two Board | 22.2 | 0.57 |

| CLBB730 | Three Board | 31.3 | 0.8 |

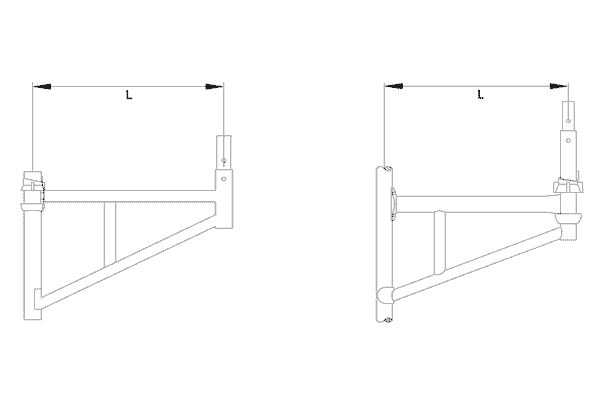

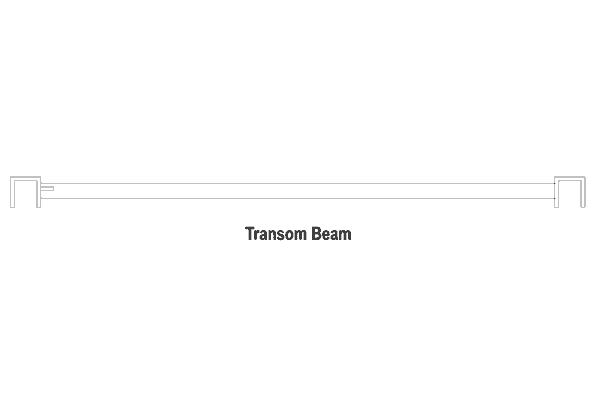

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLTB914 | 3′ Transom Beam | 36 | 0.914 |

| CLTB1219 | 4′ Transom Beam | 48 | 1.219 |

Cuplock Scaffolding – The Ultimate FAQ Guide

Have you ever heard of cuplock scaffolding before? If yes, and you’re just interested in learning more about it, then being here is great for you because we’ll let you in on top-tier information about cuplock scaffolding you’ve never encountered before.

If you answered no, though, don’t worry, because we’ll briefly let you catch up as we’ll discuss cuplock scaffolding’s fundamentals, too!

We don’t want to make you wait, so, let’s head right onto the guide!

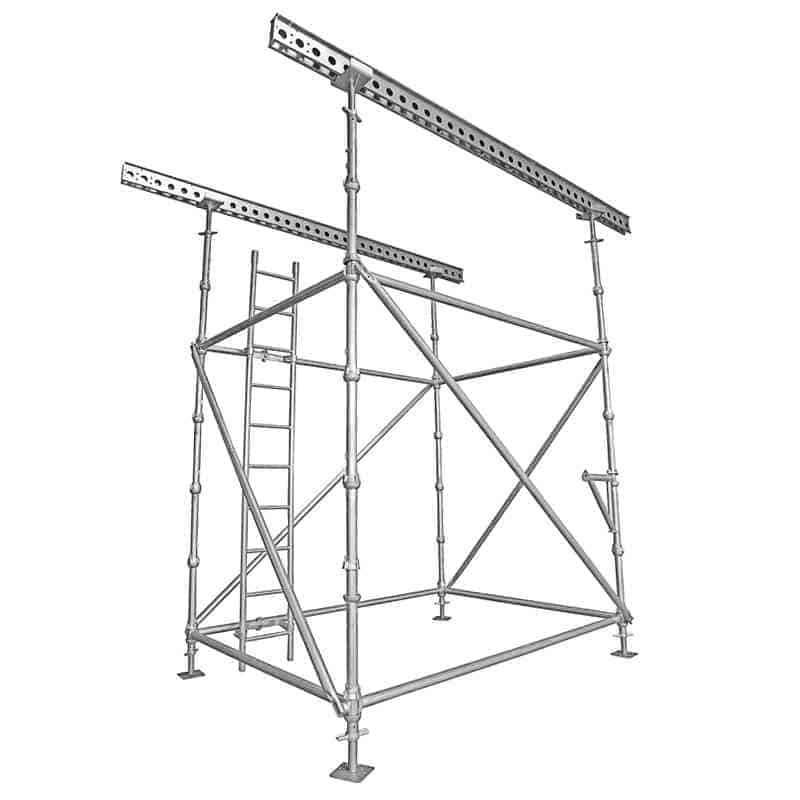

What is Cuplock Scaffolding?

Cuplock scaffolding is a strong and sturdy system that’s used in the construction and structural sector. Their purpose is to support workers and operators, as well as the rise of materials, too.

Its name “cuplock” is because it features cup-shaped components that easily lock and bond together. What this does is give and provide secure and efficient framework for construction, renovation, maintenance, repairs, or whatever that needs it.

If you’re wondering why cuplock scaffolding is a hit, it is because of its simplicity, quick assembly, and adaptability to different projects and structures. Furthermore, it ensures safety and stability, making it a preferred choice for construction projects globally.

Check this video out by Story Bites to learn more about what cuplock scaffold systems are!

https://youtu.be/fnJw0xLZE5s?si=fDyo_LMHvcRM_0ke

Key Features of Cuplock Scaffolding

1. Simple to Use

- Prefabricated Design: Cuplock parts come with welded node locking devices. Erection and dismantling require only basic tools like a hammer.

- Quick Assembly: The locking mechanism involves a fixed bottom cup and a sliding top cup, ensuring quick and secure connections.

- Ease of Handling: Lightweight components make it easier for workers to maneuver, assemble, and disassemble the scaffolding system.

2. Safety for Construction

- High-Strength Steel: Manufactured from S355 steel grade with a 3.2mm wall thickness for superior load capacity.

- Robust Cups: Fixed bottom cups are made from 5mm steel plates to securely hold ledgers and braces.

- Drop-Forged Top Cups: Designed to absorb hammer strikes without deformation, ensuring a stable and secure assembly.

3. Easy to Handle

- Cuplock scaffolding is 20% lighter than traditional scaffolding pipes, simplifying transport and on-site handling.

- Components are packed in steel pallets, allowing for safe and efficient loading and unloading using forklifts.

4. Time and Cost Efficiency

- Faster Erection: Saves 30-50% of construction time compared to traditional scaffolding systems.

- Longevity: Hot-dip galvanized finish provides a lifespan exceeding 10 years, reducing long-term replacement and maintenance costs.

5. Flexible Applications

Cuplock scaffolding can adapt to a wide range of construction needs, including:

- Facade scaffolding.

- Formwork support.

- Maintenance access.

- Stair access and birdcages.

- Mobile scaffolding systems.

- Edge protection and handrails.

It is also ideal for unconventional structures like curved or cantilevered frames.

Cuplock Scaffolding Specifications

Dimensions

- Diameter: OD 48.3mm.

- Thickness: Standard 3.2mm (4.0mm available for higher load capacities).

- Steel Grade: S355 (high-strength) or S235.

- Finish: Hot-dip galvanized or painted/powder-coated.

- Compliance Standards: EN 12810.

Maximum Construction Heights

- Single Scaffold (Putlog): 24 meters.

- Double Scaffold: 50 meters.

- Cantilever Scaffold: 20 meters.

- Full Framing Scaffold: 30 meters.

For heights exceeding 40 meters, professional design and load-bearing calculations are essential to ensure safety and structural integrity.

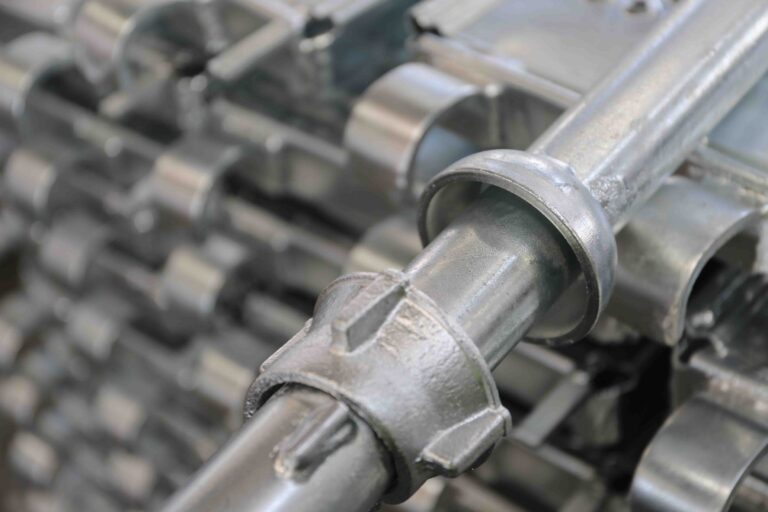

Node Locking Mechanism

The cuplock system features an innovative node locking design:

- Standards: Welded with a combination of bottom and top cups at 500mm intervals.

- Ledges: Each horizontal tube includes ledger blades at both ends for secure attachment to the bottom cups.

- Connection Points: One node can securely hold up to four ledger blades simultaneously, allowing multi-directional connections.

Cuplock Load and Safety Data

Load Capacity

Cuplock scaffolding undergoes rigorous testing to ensure safety. The following data provides guidance for load calculations:

3-Tier Cuplock Tower

- Failure Load: 101.62 KN.

- Safety Load Capacity: 33.87 KN (with a 3:1 safety factor).

3m Standard

- Failure Load: 153.47 KN.

- Safety Load Capacity: 51.16 KN (with a 3:1 safety factor).

Base Jacks

| Height (mm) | Ultimate Load (KN) | Safety Load (KN) |

|---|---|---|

| 200 | 143 | 47.67 |

| 400 | 106 | 35.33 |

| 600 | 135 | 45.00 |

Horizontals

| Length (m) | Ultimate Load (KN) | Safety Load (KN) |

|---|---|---|

| 0.5 | 48 | 16 |

| 1.0 | 21 | 7 |

| 2.0 | 10 | 3.30 |

Cuplock Components

Standards

Standards are vertical components with welded cups at regular intervals for ledger and brace connections. Available sizes range from 0.5m to 3.0m.

| Length | Weight (kg) |

|---|---|

| 1.0m | 6.31 |

| 2.0m | 11.82 |

| 3.0m | 17.34 |

Ledgers

Horizontal members with ledger blades at both ends for connection.

| Length | Weight (kg) |

|---|---|

| 1.0m | 3.92 |

| 2.0m | 7.54 |

| 2.5m | 9.35 |

Diagonal Braces

Diagonal braces ensure structural stability and are available in swivel blade or snap-type designs.

| Type | Weight (kg) |

|---|---|

| Swivel Blade Brace | 8.25–12.1 |

| Snap Brace | 12.1–14.5 |

Steel Planks

Steel planks provide secure platforms for workers. Hook-on designs simplify placement and adjustment.

| Length (m) | Weight (kg) |

|---|---|

| 3.0 | 17.34 |

| 6.0 | 30.27 |

Special Components

- Intermediate Transoms: Support wider scaffold bays.

- Hop-Up Brackets: Enable additional platform levels.

- Steel Ladders and Brackets: Provide safe and efficient access.

Cuplock Pricing

Cuplock scaffolding costs depend on:

- Raw Materials: Sourced from in-house steel mills for reduced costs.

- Manufacturing Efficiency: Automated production ensures competitive pricing.

- Finishing Options: Galvanized or painted finishes.

Applications of Cuplock Scaffolding

- Residential and commercial construction.

- Maintenance projects.

- Formwork and concrete slab support.

- Event staging and temporary structures.

Cuplock scaffolding offers a perfect blend of strength, simplicity, and flexibility. Its modular design and high load capacity make it an ideal choice for diverse construction needs. Contact us for competitive pricing and expert guidance tailored to your project!

Who Invented Cuplock Scaffolding?

The idea behind cuplock scaffolding was neither founded nor invented by a single person or company. Through constant and consistent evolution and development in the construction and architectural industry, different companies tried adapting to it, collaborating and innovating until they came up with it.

However, Lyndon SG, a UK provider of specialized access, created Cuplok and has been hailed as one of the manufacturers that offered the best and highest quality of cuplock scaffolding. This particular system has been used by many manufacturers since its arrival in the market.

NOTE: Just to be clear, Lyndon SGB did not invent cuplock. They released and founded Cuplok, their brand of specialized type of cuplock scaffolding structure.

Is Cuplock Scaffolding Safe?

Yes, it is. In case you weren’t aware, Cuplock scaffolding is built and designed with a strong emphasis on operational safety. Thanks to its secure locking mechanism and robust structure, the risk of accidents is minimized.

Construction companies, businesses, and professionals use Cuplock scaffolding because of its reliable design and adaptability to different construction and structural needs. It is safe because regular and standard inspections and adherence to safety guidelines ensure the continuous safe utilization of Cuplock scaffolding on sites and projects.

It is, therefore, crucial for businesses and scaffolding erectors to follow proper assembly procedures and industry standards.

Here’s a video erecting a cuplock scaffold. Here, you can see how safe and secure it is!

https://youtu.be/veF4uSUtrEY?si=HeP6z6H_Ovwzmg-t

Cuplock Scaffolding Parts Names

The parts of cuplock scaffolding structures don’t fall very far from ringlock scaffolding components. But for the benefit of everyone, we’ll name a few of the most important and most common components of a cuplock scaffolding system.

Base or Foundation

The component situated at the bottom-most part or at the base of the scaffolding structure. This is the part responsible in making the entire structure stand tall and sturdy. They help stabilize the entire structure upward.

Standards

The vertical components; the building blocks of scaffolding structures. They’re the parts that give the height needed. The more standards, the higher the scaffolding structure would be.

Diagonal Braces

Diagonal braces are the angled tubes that go along the x and y axis. These components add support and durability to the overall integrity of the scaffold.

Horizontals or Ledgers

The counterpart of the standards. They’re the horizontal components that are often the reason for the stability of the standard. Correctly-placed ledgers add strength and rigidity to the overall scaffold.

Universal Jacks

These are the universally-adjustable components usually seen at the bottom or base part of the scaffold. They’re responsible for the stabilization of the structure, even if it’s erected at an uneven surface.

Cups

Of course, we can’t forget about the cups. The cups are what makes cuplock scaffolding unique. There’s what we call the top cup, bottom cup, and the ledger blade. These are the components that catch and lock standards that have the slits dedicated for the cups.

Transoms

These are the horizontal parts that support the boards and help in enhancing the load or weight capacity of the entire scaffold. There are also intermediate transoms, which just add further support to the boards.

Whether you’re looking for parts independently or you’re just looking to learn, check out the names of the components or parts of cuplock scaffolds in Alibaba!

What is H-Frame Scaffolding?

An H-Frame scaffolding structure is a sturdy and commonly resorted-to construction support system. These systems usually consist of vertical frames resembling the letter ‘H,’ offering strength and stability, hence the name H-frame scaffolding.

In case you were wondering, H-frames connect horizontally to create a secure platform for workers and materials. Furthermore, H-frame scaffolding is also loved by many because they’re simple, easy to assemble, and extremely versatile – meaning, it’s not limited to just a few projects!

H-frame scaffolding systems are safe, easy, and is often considered by many as their go-to system.

What is the Spacing in Cuplock Scaffolding?

According to several sources, cuplock scaffolding systems are usually distanced to be between 500mm and 1000mm depending on the requirement. This spacing, however, can vary, especially if you’re working with a custom cuplock scaffolding manufacturing company.

This strategic spacing is what allows cuplock scaffolding systems to be able to carry and bear loads.

What Are the Advantages of Cuplock Scaffolding

Cuplock scaffolding wouldn’t be loved by many construction businesses if they didn’t offer excellent quality. So, let’s go and enter the discussion of what the advantages or pros of cuplock scaffolding are:

Cost-Effective

The first and probably one of the most important (and what you’re looking for) is its cost. Cuplock scaffolding systems prove that this structure is budget-friendly. Why? Because it is reusable, and, therefore, companies can maximize resources.

For beginners, this is one of the best and smartest investments you can get!

Fast and Easy Assembly

Another of its many benefits and pros is its fast erection and assembly. Because most parts are versatile, you don’t have to spend too much time thinking about which goes where – they’ll most likely be available!

Cuplock scaffolds have been designed to be set up and erected faster and quicker than other scaffolding types.

Adaptability

If there’s something we personally love about cuplock scaffolds, it is its adaptability. Imagine a complex project with an essential curvature, do you think a standard scaffold will be able to accommodate that? Let’s face it, we all want a scaffold that’s usable in many different ways – well, cuplock scaffolding is here for that!

Safety and Security

Let’s not forget the security cuplock scaffolding structures offer. Because of the fact that each standard is locked on both sides, it offers stability and safety from being accidentally misaligned. The continuous stability from the horizontal, vertical, and diagonal areas make it stronger, more stable, and a lot stiffer.

Availability

Last but most definitely not least is its availability. Most, if not all scaffolding manufacturers and suppliers often have materials and components readied for cuplock scaffolding requests. Unlike other types of locks, cuplocks are actually easier to create and fabricate, making it one of the best and most available pieces of component in scaffolding!

What Are the Disadvantages of Cuplock Scaffolding

Let’s not be one-sided. Saying that cuplock scaffolding is all about advantages and benefits is wrong. In fact, there are a lot of other things and factors you need to consider before deciding to go with it:

Bulky and Heavier

The components of Cuplock scaffolds are strong, but they can be bulkier and heavier than your usual scaffolding components. Although they’re efficient in construction, they can be bulky during transportation and locomotion.

Logistically, it can pose problems if not planned and prepared for correctly.

Higher Initial Cost

Cuplock scaffolding systems are actually cheaper, in the long-run. However, the initial cost is slightly higher than what most people would expect. They’re a lot expensive and costlier than other scaffolding types in terms of shelling money out.

If you’re within a budget, the upfront costs of cuplock scaffolding might not be a good fit for you.

Skill Requirement

Lastly, skill dependency or skill requirement. Cuplock scaffolding is good and effective, only if it’s set up and erected the right way. It takes time to learn and to understand the principle of how cuplock scaffolding structures work, and non-experienced workers might slow the process down.

Furthermore, unwanted accidents can be the cost of errors or improper assembly or establishments of the scaffolding structure.

Where Can You Get Good-Quality Cuplock Scaffolding?

You’re not the only one who’s trying to look for excellent-quality cuplock scaffolds. There are a lot. As a matter of fact, here in China, cuplock scaffolds are considered one of the oldest and most-sought-after types of scaffolding structures.

It’s safe to say that they’re the “favorites,” and it’s simply because of the price and overall availability of it. Chinese scaffolding solutions businesses are known and considered scarce in the market, and that’s why we here at Rapid Scaffolding gave it our best when it comes to scaffolding formwork, designs, and manufacturing.

Our 20+ year-experience has been key in giving us the opportunity to be at the top of our game. We’re employed with some of the industry’s most talented and most reliable engineers and experts who always innovate and give the best out of what we have.

Working With Rapid Scaffolding For Your Cuplock Scaffold Needs

In China, our team here at Rapid Scaffolding has been regarded to as the leading and most-trusted cuplock scaffolding manufacturer for over 2 decades. Our experience has been pleasant, day-in, day-out, and we’ve produced a wide array of scaffolding structures to our clientele.

Among our many specializations include cuplock scaffolding, where we’ve proven our expertise and skill as we pushed the boundaries of the scaffolding industry to the max! In all our scaffolding manufacturing, we’ve proven quality and quantity going side by side!

Our goal is to ensure that all projects become easier and safer, as well as ensure that we provide the best and highest level of credibility, profession, mutual benefit, and overall excellence.

Why Trust Rapid Scaffolding?

Our team here at Rapid Scaffolding have provided a wide array of evidence on why we’re the best. From gaining accreditation from world-industry standards to producing the best and highest quality of cuplock scaffolding, we got just what you need!

So, if you find yourself in need of shoring frames, octagonlock scaffolding, Kwikstage scaffolding, or the usual ringlock scaffolding, don’t hesitate to contact us!

Reach out to us via phone or email and we’ll send a free quotation over!

Contents

- Cuplock Scaffolding Manufacturer in China

- Rapid Cuplock Scaffolding Video

- Why Choose Rapid?

- Cuplock Scaffold Specifications:

- Cuplock Standard

- Cuplock Ledger

- Cuplock Diagonal Brace

- Cuplock Truss

- Cuplock Board Bracket

- Cuplock Transom Beam

- Cuplock Scaffolding – The Ultimate FAQ Guide

- What is Cuplock Scaffolding?

- Key Features of Cuplock Scaffolding

- 1. Simple to Use

- 2. Safety for Construction

- 3. Easy to Handle

- 4. Time and Cost Efficiency

- 5. Flexible Applications

- Cuplock Scaffolding Specifications

- Dimensions

- Maximum Construction Heights

- Node Locking Mechanism

- Cuplock Load and Safety Data

- Load Capacity

- Cuplock Components

- Standards

- Ledgers

- Diagonal Braces

- Steel Planks

- Special Components

- Cuplock Pricing

- Applications of Cuplock Scaffolding

- Who Invented Cuplock Scaffolding?

- Is Cuplock Scaffolding Safe?

- Cuplock Scaffolding Parts Names

- Base or Foundation

- Standards

- Diagonal Braces

- Horizontals or Ledgers

- Universal Jacks

- Cups

- Transoms

- What is H-Frame Scaffolding?

- What is the Spacing in Cuplock Scaffolding?

- What Are the Advantages of Cuplock Scaffolding

- Cost-Effective

- Fast and Easy Assembly

- Adaptability

- Safety and Security

- Availability

- What Are the Disadvantages of Cuplock Scaffolding

- Bulky and Heavier

- Higher Initial Cost

- Skill Requirement

- Where Can You Get Good-Quality Cuplock Scaffolding?

- Working With Rapid Scaffolding For Your Cuplock Scaffold Needs

- Why Trust Rapid Scaffolding?

- Get A Quote Now !