Which Type of Scaffolding is the Best?

Confused about which type of scaffolding to choose? The best type depends on your project needs, load requirements, and working height. Scaffolding types vary in function and suitability for different tasks.

The best type of scaffolding depends on your project. Supported scaffolding is versatile and widely used, suspended scaffolding is ideal for tall buildings, and rolling scaffolding offers mobility. For heavy-duty work, steel scaffolding is the strongest and most durable option, ensuring safety in industrial projects.

When looking for reliable scaffolding, there are a few key factors to consider:

- Choose a reputable supplier or rental company. Look for established companies with good reputations and safety records. Some well-known scaffolding manufacturers and suppliers include:

- Layher

- SGB

- Altrad

- Safway

- Brand Safway

- PERI

- Ensure the scaffolding meets relevant safety standards and regulations. In the US, scaffolding should comply with OSHA standards. In other countries, look for compliance with local regulations.

- Consider the specific needs of your project:

- Type of scaffolding required (e.g. supported, suspended, mobile)

- Load capacity needed

- Height and accessibility requirements

- Duration of use

- For large or complex projects, work with a scaffolding company that can provide design and engineering services to create a custom solution.

- If renting, make sure the company provides proper inspection, maintenance, and assembly services.

- Ask about training options for workers who will be using the scaffolding.

- Get quotes from multiple providers to compare pricing and services.

Some good places to start your search include:

- Local construction equipment rental companies

- National scaffolding suppliers with local branches

- Scaffolding manufacturers’ websites to find authorized dealers

- Industry associations like the Scaffold & Access Industry Association (SAIA) for member listings

Be sure to thoroughly vet any company you’re considering and ask for references from past clients. Proper scaffolding is critical for worker safety, so it’s important to choose a reliable, experienced provider.

Now that you know the general types, let’s explore the advantages and ideal uses of supported, suspended, rolling, and steel scaffolding to determine the best option for your specific project needs.

Contents

- Which Type of Scaffolding is the Best?

- What is Supported Scaffolding, and When is it Best?

- What is Suspended Scaffolding, and When Should It Be Used?

- What is Rolling Scaffolding, and Why is it Useful?

- What is Steel Scaffolding, and When is it Best?

- What is Aluminum Scaffolding, and When is it Best?

- What Are the Two Basic Scaffolds?

- Conclusion

What is Supported Scaffolding, and When is it Best?

Unsure when to use supported scaffolding? It’s versatile, stable, and widely used in construction, providing support from the ground up for multiple tasks such as bricklaying and plastering.

Supported scaffolding is ideal for construction projects that require stable platforms built from the ground. It’s commonly used in tasks like bricklaying, roofing, and plastering, offering stability and flexibility for various heights and loads.

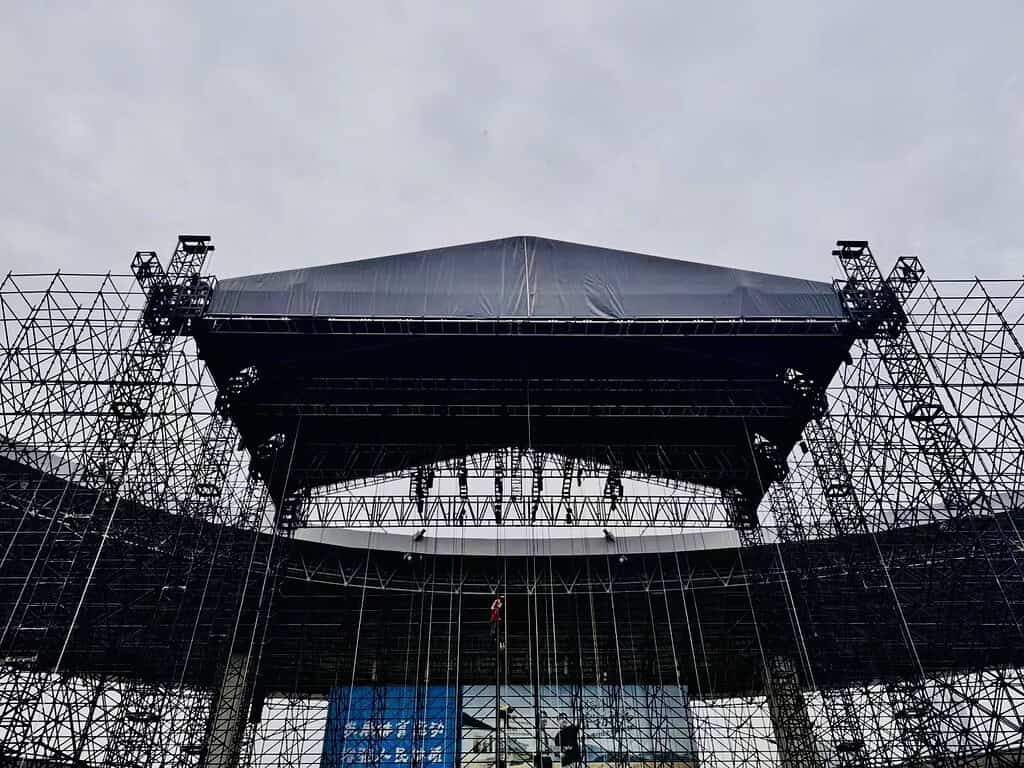

Supported scaffolding is one of the most common and versatile types of scaffolding, ideal for projects where a stable, ground-supported platform is needed. This type of scaffolding is constructed from the ground up using vertical standards, horizontal ledgers, and cross braces to provide a sturdy framework. It’s commonly used for jobs like bricklaying, roofing, or plastering and can be customized to fit different heights and load capacities. Supported scaffolding is especially useful for projects where the scaffold needs to remain in place for an extended period. It’s safe, reliable, and can support multiple workers, making it a popular choice for general construction and maintenance work.

What is Suspended Scaffolding, and When Should It Be Used?

Working on tall buildings? Suspended scaffolding is perfect for high-rise tasks like window cleaning and painting, offering mobility while hanging from the roof or upper floors of a structure.

Suspended scaffolding is used for tall structures where ground-based scaffolding isn’t practical. It’s suspended from the roof and is commonly employed for tasks like window cleaning, painting, or exterior repairs on high-rise buildings.

Suspended scaffolding is an excellent choice for projects involving tall structures or high-rise buildings where it’s not feasible to build scaffolding from the ground. This type of scaffolding is suspended from the roof using ropes, cables, or chains and can be raised or lowered as needed. It’s commonly used for tasks like window cleaning, painting, or exterior maintenance on skyscrapers. One of the key benefits of suspended scaffolding is its ability to provide workers with mobility at significant heights without the need for large amounts of material at ground level. However, it requires specialized safety measures and equipment to ensure the stability of the platform and worker safety.

What is Rolling Scaffolding, and Why is it Useful?

Need flexibility and mobility? Rolling scaffolding offers the convenience of wheels, allowing workers to move easily between areas without dismantling the structure, making it perfect for painting and maintenance.

Rolling scaffolding is ideal for tasks that require frequent movement, such as painting or maintenance. Mounted on wheels, it allows workers to move the scaffolding without needing to dismantle it, making it efficient for large or multi-area projects.

Rolling scaffolding is equipped with wheels or casters, allowing workers to move the scaffold easily across different sections of a building or workspace without disassembling it. This type of scaffolding is ideal for tasks that require frequent movement, such as painting, window cleaning, or maintenance on long walls or large buildings. The ability to reposition the scaffolding quickly improves efficiency, reducing downtime and labor costs. Additionally, rolling scaffolding is typically light and easy to maneuver, making it suitable for indoor use or areas where the scaffold needs to be relocated often. Safety features like locking wheels ensure stability when the scaffolding is in use.

What is Steel Scaffolding, and When is it Best?

Handling heavy loads? Steel scaffolding is known for its strength and durability, making it the best choice for industrial construction, steelwork, and projects that involve heavy materials or equipment.

Steel scaffolding is the strongest type, designed for industrial projects that require high load-bearing capacity. It’s ideal for tasks involving heavy equipment, steel fabrication, or concrete work, ensuring durability and safety in high-risk environments.

Steel scaffolding is the strongest and most durable type of scaffolding, built to withstand the weight of heavy materials, equipment, and multiple workers. It’s commonly used in industrial construction, high-rise buildings, and large-scale infrastructure projects, where the load-bearing capacity and strength of steel are essential. Steel scaffolding is designed to handle extreme conditions, including exposure to the elements and long-term use. Its durability makes it the go-to choice for projects that require both safety and reliability. While it may be more expensive and heavier to transport than aluminum scaffolding, the benefits in terms of strength and longevity make steel scaffolding the best option for demanding construction tasks.

What is Aluminum Scaffolding, and When is it Best?

Looking for lightweight scaffolding? Aluminum scaffolding offers portability and ease of assembly, making it ideal for smaller projects where frequent movement and lighter loads are required.

Aluminum scaffolding is the best choice for smaller tasks where lightweight and portability are key. It’s ideal for painting, light construction, or window cleaning where frequent movement and easy setup are needed.

Aluminum scaffolding is an excellent option for projects that prioritize portability and ease of assembly. Being much lighter than steel, it’s easier to move, making it suitable for tasks like window cleaning, painting, or light construction where frequent relocation of the scaffolding is required. Aluminum scaffolding is corrosion-resistant and easy to handle, offering quick assembly and disassembly for contractors. However, due to its lightweight nature, it is not recommended for projects that involve heavy loads or require maximum durability. For smaller, short-term projects, aluminum scaffolding provides the convenience and flexibility needed for efficiency.

What Are the Two Basic Scaffolds?

Confused about the basics? The two basic types of scaffolds are supported scaffolding, which is built from the ground, and suspended scaffolding, which hangs from rooftops for access to high areas.

The two basic types of scaffolding are supported scaffolding, built from the ground up, and suspended scaffolding, which hangs from ropes or cables. Supported scaffolding is more versatile, while suspended scaffolding is used for high-rise work.

The two basic types of scaffolding are supported scaffolding and suspended scaffolding. Supported scaffolding is the most common type, built from the ground with vertical supports, ledgers, and braces to provide a stable platform for workers. It’s ideal for construction tasks at various heights, offering flexibility in assembly. Suspended scaffolding, on the other hand, is used for high-rise work or situations where it’s impractical to build from the ground. It hangs from the roof using ropes or cables and is often used for tasks like window cleaning, exterior painting, or repairs on tall buildings. Both types serve different purposes, and the choice depends on the height and load requirements of the project.

Conclusion

In conclusion, the best type of scaffolding depends on your project needs. Supported scaffolding is ideal for general construction, suspended scaffolding for high-rise work, rolling scaffolding for mobile tasks, steel scaffolding for industrial projects, and aluminum scaffolding for lightweight tasks. Choose based on load, height, and mobility requirements.