What Is the Formwork for a Wall?

Struggling to construct durable walls? Wall formwork provides a reliable solution for shaping and supporting concrete during curing, ensuring precision and strength for both small and large construction projects.

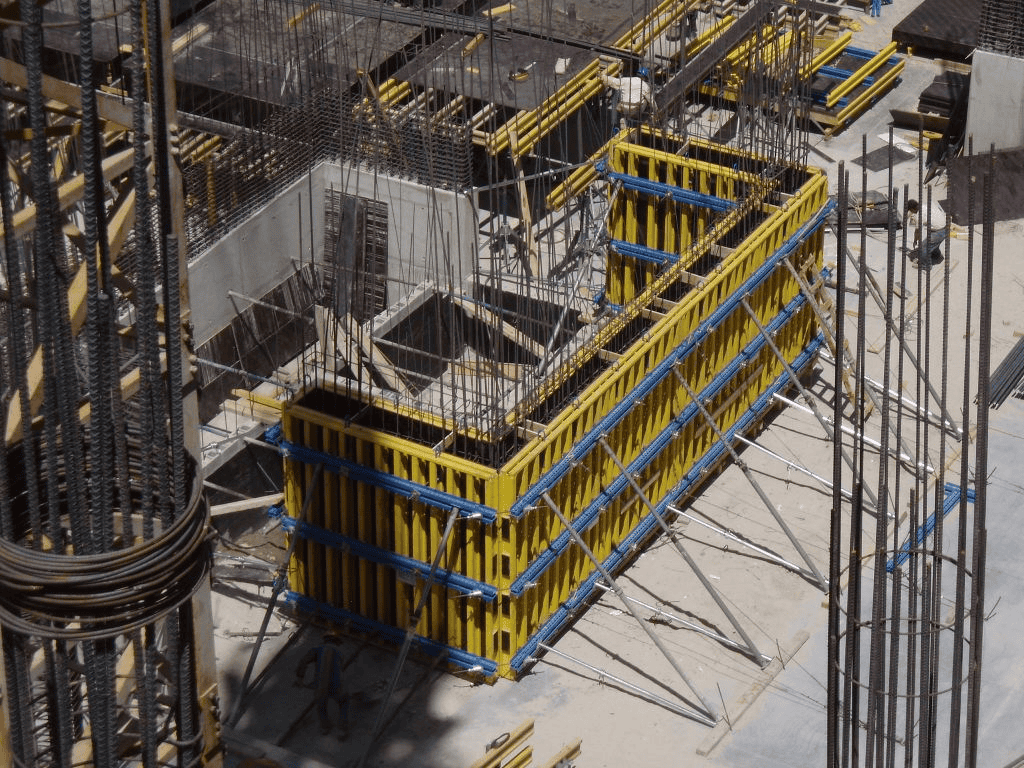

Wall formwork is a temporary mold used to shape and support vertical concrete structures until they harden. It includes components like panels, ties, and braces, ensuring structural stability and accuracy.

Below, we explore the types, components, and benefits of wall formwork, as well as best practices for its use in achieving high-quality, durable concrete structures.

What Is Wall Formwork, and Why Is It Used?

Curious about wall formwork? It’s essential for constructing vertical concrete structures, ensuring stability during curing and delivering precise, high-quality finishes in construction projects.

Wall formwork is a temporary structure used to hold concrete in place during curing. It provides stability, ensures accurate dimensions, and enhances the durability and finish of vertical structures.

Wall formwork is a temporary mold designed to hold and shape concrete while it cures, providing essential support for vertical structures like walls and columns. Its purposes include:

- Shaping Concrete: Ensures the desired height, width, and alignment.

- Supporting Concrete: Prevents deformation or collapse during the curing process.

- Enhancing Safety: Stabilizes structures to protect workers and the construction site.

- Ensuring Quality Finishes: Delivers smooth and even surfaces, reducing the need for additional work.

Wall formwork is crucial for achieving durable, accurate, and aesthetically pleasing results in concrete construction.

What Type of Formwork Is Used for Walls?

Unsure about the best options for walls? Different types of formwork cater to various project needs, offering flexibility, durability, and cost-effectiveness.

Commonly used formwork for walls includes timber, steel, aluminium, plastic, and modular systems. Each type offers unique advantages depending on the project scale, complexity, and budget.

The types of formwork commonly used for walls include:

- Timber Formwork: Cost-effective for small projects, easy to assemble.

- Steel Formwork: Durable and reusable, suitable for large-scale projects.

- Aluminium Formwork: Lightweight and resistant to corrosion, ideal for medium-scale projects.

- Plastic Formwork: Lightweight and reusable, good for repetitive tasks.

- Modular Formwork Systems: Prefabricated panels that are versatile and efficient for complex designs.

Selecting the appropriate formwork type depends on the structure’s requirements and project constraints.

What Are the Components of Wall Formwork?

Wondering how wall formwork is constructed? It includes essential components like panels, ties, and braces, each playing a vital role in supporting and shaping concrete walls during curing.

Wall formwork consists of panels, ties, braces, and props. These components work together to maintain the structure’s shape, prevent leaks, and ensure the concrete hardens evenly and securely.

Wall formwork is composed of several key components:

- Panels: The primary molds that shape the concrete. These can be made of timber, plywood, steel, aluminium, or plastic.

- Ties: Hold the panels together and prevent bulging due to concrete pressure.

- Braces: Provide external support to keep the formwork stable and in position.

- Props: Maintain stability and support for formwork during concrete pouring.

Each component is essential for the stability, accuracy, and durability of the wall formwork system.

What Are the Benefits of Using Wall Formwork?

Seeking better construction outcomes? Wall formwork enhances precision, durability, and efficiency, making it indispensable for high-quality concrete walls in modern construction.

Wall formwork offers benefits like enhanced structural stability, faster construction, and improved surface finishes. It minimizes material waste and ensures safety during the construction process.

The advantages of using wall formwork include:

- Structural Integrity: Prevents deformation and ensures uniformity in the finished structure.

- Efficiency: Prefabricated systems speed up assembly and dismantling.

- Durability: Modern materials like steel and aluminium extend formwork life.

- Cost-Effectiveness: Reusable systems reduce overall expenses.

- Safety: Stabilizes walls during curing to prevent accidents.

These benefits make wall formwork an essential part of modern construction projects.

What Are the Best Practices for Using Wall Formwork?

Want to optimize your project? Proper setup, regular maintenance, and timely removal are key to ensuring successful results when working with wall formwork.

Best practices include choosing the right material, ensuring proper alignment, applying release agents, and regularly inspecting components for damage. These steps ensure quality and safety in construction.

To get the best results from wall formwork:

- Choose the Right Material: Match the system to the project’s size and complexity.

- Ensure Proper Alignment: Prevent uneven surfaces or structural weaknesses.

- Use Release Agents: Simplify removal and protect surfaces.

- Inspect Components Regularly: Check for damage or wear to maintain safety and precision.

- Follow Removal Guidelines: Remove the formwork at the correct time to avoid structural damage.

Following these practices ensures efficient, safe, and high-quality construction.

Conclusion

Wall formwork is an essential tool in construction, providing stability and precision for vertical concrete structures. By choosing the right system and following best practices, builders can achieve durable and high-quality results.