Are There Any Methods to Check the Formwork?

Worried about construction quality? Proper methods for checking formwork ensure safety, stability, and durability, reducing risks of failure and improving the quality of your concrete structures.

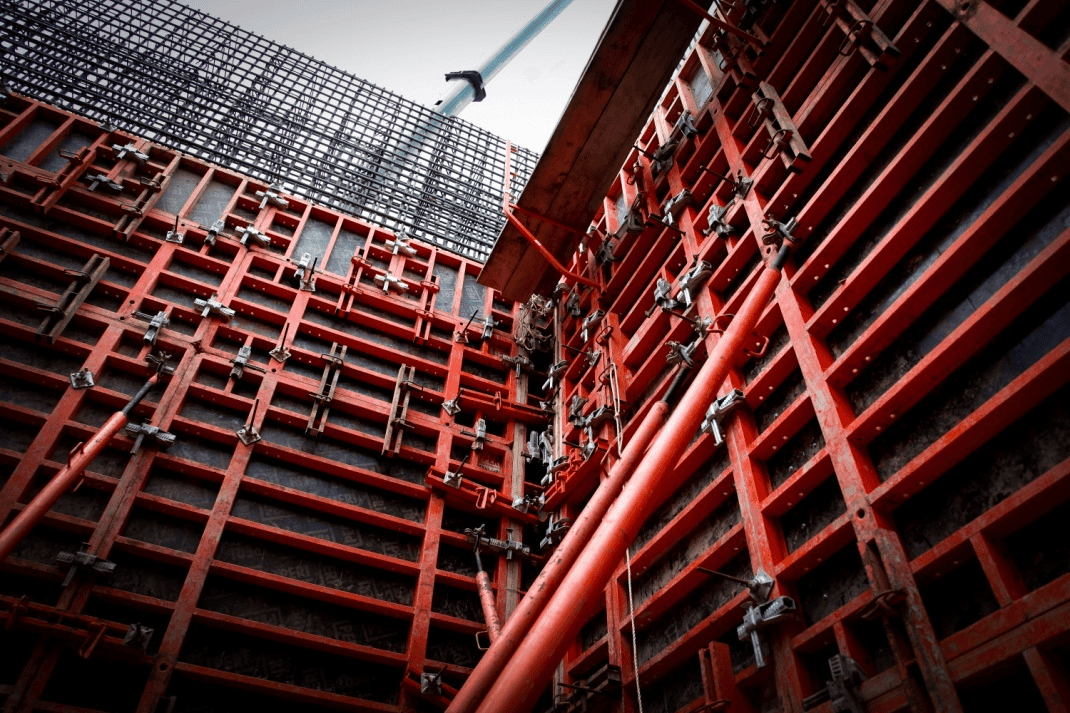

Checking formwork involves inspecting its alignment, stability, load-bearing capacity, and material quality. Methods include visual inspections, structural testing, and adherence to design specifications. These measures ensure safe and efficient concrete construction.

Below, we detail effective methods for inspecting and testing formwork, ensuring your concrete structures are built safely, efficiently, and in compliance with construction standards.

Why Is It Important to Check Formwork?

Why does checking formwork matter? Ignoring inspections can result in costly errors, structural failures, and safety risks. Proper checks improve durability, precision, and ensure compliance with construction standards.

Checking formwork is crucial to prevent structural defects, ensure proper alignment, and verify load capacity. Regular inspections maintain construction safety and improve the overall quality of concrete structures.

Checking formwork is essential for:

- Structural Stability: Prevents collapse and ensures the formwork can support concrete loads.

- Alignment Precision: Avoids defects in concrete dimensions.

- Safety: Reduces accidents during and after pouring.

- Cost Efficiency: Detects and resolves issues early to prevent expensive rework.

Effective formwork checks contribute to efficient, high-quality construction.

What Are the Key Methods to Check Formwork?

Are you using the right methods for formwork inspection? Proper checks, including visual assessments and load testing, ensure safety and compliance in construction projects.

Methods to check formwork include visual inspections, load-bearing tests, and alignment verification. These methods help prevent errors, improve safety, and ensure construction meets design specifications.

Reliable methods for checking formwork include:

- Visual Inspections: Look for cracks, rust, and material defects.

- Alignment Checks: Use levels, plumb lines, or laser tools.

- Load Testing: Ensure the formwork can bear the concrete weight.

- Material Assessments: Verify components meet required standards.

- Compliance Verification: Confirm that the setup aligns with design specifications.

Implementing these checks minimizes risks and enhances construction quality.

How Can Alignment of the Formwork Be Checked?

How do you achieve perfect alignment? Misaligned formwork leads to structural defects and inefficiency. Regular checks with advanced tools prevent costly errors.

Alignment can be checked using levels, plumb bobs, and laser instruments. These tools help ensure the formwork is positioned correctly, maintaining accuracy and preventing structural inconsistencies in concrete.

Alignment can be checked by:

- Using Levels: Ensure horizontal and vertical components are accurate.

- Plumb Bobs: Verify the perpendicularity of vertical elements.

- Laser Instruments: Maintain precision in large projects.

- Visual Inspections: Identify misalignments or gaps.

Correct alignment improves the structural integrity and appearance of concrete structures.

What Are the Best Practices for Formwork Inspections?

Are you following best practices? Proper inspections reduce risks and ensure compliance, delivering better results for your construction projects.

Best practices for formwork inspection include regular assessments, advanced tools, adherence to design standards, and thorough documentation. These steps ensure safety and quality in construction.

Best practices include:

- Frequent Inspections: Conduct checks before and during concrete pouring.

- Use Advanced Tools: Levels, lasers, and sensors improve accuracy.

- Document Results: Maintain records of findings for accountability.

- Train Workers: Ensure the team understands inspection protocols.

Implementing these practices ensures the safety and quality of your project.

Conclusion

Regularly inspecting formwork using reliable methods and tools is crucial for safe and efficient concrete construction. Adopting proper practices ensures structural integrity, minimizes risks, and enhances project quality.