Encofrado de losas

El encofrado de losa es una estructura temporal que sostiene la losa de hormigón mientras se vierte y se cura. Está formado por una serie de paneles, vigas y puntales que se disponen para crear la forma y el tamaño deseados de la losa.

El encofrado de losas es una parte esencial del proceso de construcción con hormigón. Garantiza que la losa se coloque correctamente y que sea seguro caminar sobre ella y trabajar sobre ella una vez que se haya curado.

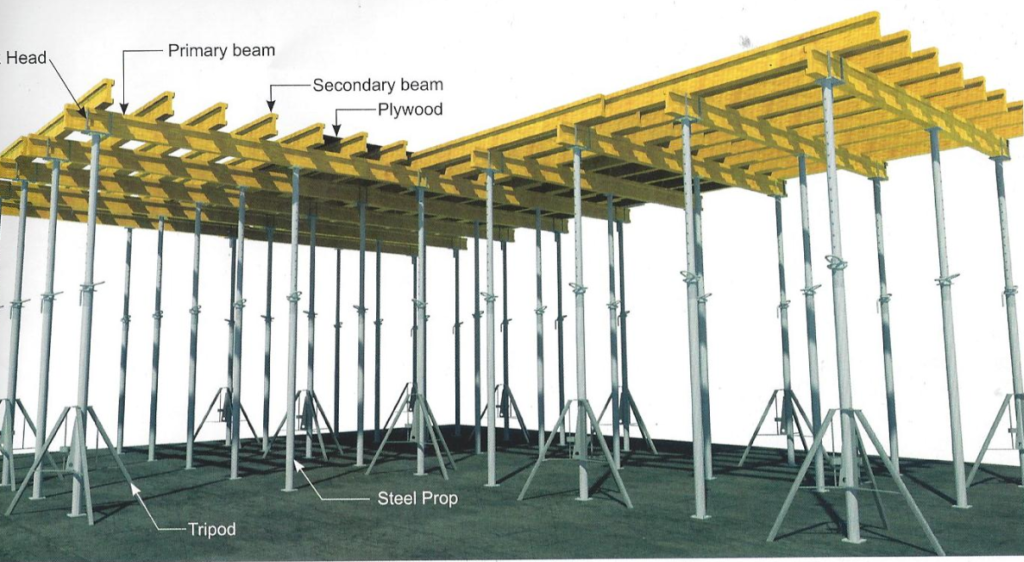

Sistema de encofrado de mesas para losas H20

El sistema de encofrado de mesa para losas H20 es una forma rápida, eficiente y segura de encofrar losas de hormigón. El sistema consta de vigas de madera H20, puntales de acero, cabezales de mesa y abrazaderas de mesa. Las vigas se conectan a los cabezales de mesa con abrazaderas de mesa y los cabezales de mesa se sostienen con los puntales de acero. El sistema se puede utilizar para encofrar losas de hasta 450 mm de espesor.

Sistema de encofrado Flex-Table

El sistema de encofrado Flex-Table es una forma versátil y eficiente de encofrar losas de hormigón. El sistema consta de tubos de acero, vigas de madera, triángulos de acero y paneles de encofrado. Los tubos y las vigas se conectan para formar el marco del sistema y los triángulos se utilizan para proporcionar soporte adicional. Los paneles se fijan al marco para crear la forma y el tamaño deseados de la losa.

Preguntas frecuentes

¿Qué es el encofrado de losas?

El encofrado de losa es una estructura temporal que sostiene la losa de hormigón mientras se vierte y se cura. Está formado por una serie de paneles, vigas y puntales que se disponen para crear la forma y el tamaño deseados de la losa.

¿Cuáles son los diferentes tipos de encofrados de losas?

Existen dos tipos principales de encofrados de losas:

- Encofrado de losas tradicional: Este tipo de encofrado está formado por componentes individuales que se ensamblan en la obra. Es el tipo de encofrado más versátil, pero su montaje puede requerir mucho tiempo y mano de obra.

- Encofrado de losas modulares: Este tipo de encofrado está formado por paneles premontados de fácil montaje y desmontaje. Es menos versátil que el encofrado tradicional de losas, pero es más rápido y sencillo de utilizar.

¿Qué materiales se utilizan para el encofrado de losas?

El encofrado de losas se puede realizar a partir de una variedad de materiales, entre ellos:

- Madera: La madera es el material más común utilizado para encofrados de losas. Es resistente, duradera y relativamente económica.

- Acero: El acero es un material más duradero que la madera, pero también es más caro.

- Aluminio: El aluminio es un material ligero y resistente a la corrosión, pero también es más caro que la madera o el acero.

¿Qué es el Sistema de Encofrado de Mesas de Losa H20?

El sistema de encofrado de losas H20 es un tipo de encofrado de losas modular que se compone de vigas de madera H20, puntales de acero, cabezales de mesa y grapas de mesa. El sistema está diseñado para un montaje y desmontaje rápido y sencillo, y puede utilizarse para encofrar losas de hasta 450 mm de espesor.

¿Qué es el sistema de encofrado Flex-Table?

El sistema de encofrado Flex-Table es otro tipo de encofrado modular para losas que se compone de tubos de acero, vigas de madera, triángulos de acero y paneles de encofrado. El sistema está diseñado para brindar versatilidad y se puede utilizar para encofrar una variedad de formas y tamaños de losas.

¿Cuáles son los beneficios de utilizar sistemas de encofrado de losas?

Los sistemas de encofrado de losas ofrecen una serie de ventajas sobre los métodos de encofrado tradicionales, entre ellas:

- Velocidad: Los sistemas de encofrado de losas se pueden montar y desmontar rápidamente, ahorrando tiempo y costes de mano de obra.

- Eficiencia: Los sistemas de encofrado de losas están diseñados para una fácil manipulación y transporte, reduciendo la necesidad de equipo pesado.

- Seguridad: Los sistemas de encofrado de losas son fuertes y estables, proporcionando un entorno de trabajo seguro para los trabajadores de la construcción.

- Versatilidad: Los sistemas de encofrado de losas se pueden utilizar para formar una variedad de formas y tamaños de losas.

¿Cuáles son las precauciones de seguridad a tomar al utilizar sistemas de encofrado de losas?

Al utilizar sistemas de encofrado de losas, es importante seguir todas las precauciones de seguridad, incluidas:

- Use equipo de seguridad adecuado, como cascos, gafas de seguridad y botas con punta de acero.

- Utilice escaleras y andamios de forma segura.

- Tenga en cuenta el peso del hormigón y el riesgo de derrumbe.

- Siga todas las instrucciones del fabricante.

¿Dónde puedo encontrar más información sobre los sistemas de encofrado de losas?

Hay una serie de recursos disponibles para aprender más sobre los sistemas de encofrado de losas, incluidos:

- Sitios web de los fabricantes: Muchos fabricantes de sistemas de encofrado de losas tienen sitios web que brindan información detallada sobre sus productos.

- Publicaciones comerciales: Existe una serie de publicaciones comerciales que se centran en la construcción con hormigón y estas publicaciones a menudo incluyen artículos sobre sistemas de encofrado de losas.

- Foros en línea: Hay una serie de foros en línea donde los profesionales de la construcción con hormigón pueden discutir sobre sistemas de encofrado de losas y otros temas relacionados con la construcción con hormigón.

¡Haz una consulta!

Si tiene alguna duda, no dude en contactarnos, ¡nuestro ingeniero de soporte técnico se comunicará con usted pronto!