Table of Contents

What is System Scaffolding?

System scaffolding is a type of scaffolding that uses pre-engineered horizontal and vertical parts to create a structure.

It is a cost-effective and efficient way to construct scaffolding, popular across the world and in great demand.

System scaffolding is used in high volume settings, smaller structures, and can be used to create homogenous scaffolding bays.

It is made up of different types of scaffolding, each fulfilling a specific purpose.

System scaffolding is used in various industries, including construction, and is popular across the world.

Benefits of System Scaffolding

System scaffolding is a cost-effective and efficient way to construct scaffolding.

It is lightweight, yet sturdy, and has a unique set of features and benefits.

System scaffolding is easy to erect and disassemble, and is used by various workers, including construction workers, roofers, and painters.

It provides a safe and stable platform for workers to perform tasks at heights.

System scaffolding is adaptable and can be used in various construction projects, including building and maintenance tasks.

Modular Scaffolding

Modular scaffolding is a modern scaffolding system based on the conventional tube and coupler method.

It is designed for complex structures and provides a versatile and adaptable work platform.

Modular scaffolding is ideal for construction projects that require unique and complex structures.

It is a type of system scaffolding that uses prefabricated components to create a structure.

Modular scaffolding is a cost-effective and efficient way to construct scaffolding.

Other Types of System Scaffolds

Ringlock scaffolding is a type of system scaffolding that uses prefabricated components to create a structure.

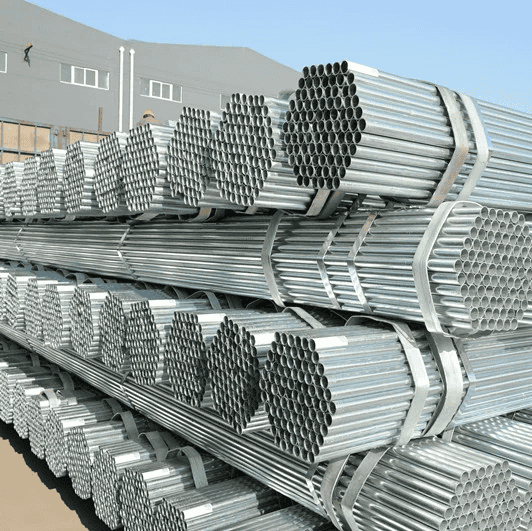

Cuplock scaffolding is a type of system scaffolding that uses galvanized steel to create a structure.

Kwikstage scaffolding is a type of system scaffolding that is popular in the UK and Australia.

Frame scaffolding is a type of system scaffolding that is commonly found on construction sites.

Shoring props are used in an array of medium-height false work and building support work, including internal demolition.

System Scaffold vs Tube and Fitting Scaffolding

System scaffolding is a type of prefabricated scaffolds, with integrated locks, pins, and connectors.

System scaffolding is more convenient in construction and shoring support, with no need for extra scaffolding couplers and fittings.

Tube and Fitting scaffolding is a traditional type of scaffolding, used in all countries for a long time.

Tubular scaffolding is more flexible, allowing for the formation of all shapes and types of scaffolding.

Scaffolding System Surface Treatment

Hot dip galvanizing is a surface treatment that provides a protective coating to the scaffolding system.

E-galvanizing is a surface treatment that provides a protective coating to the scaffolding system.

Pre-galvanizing is a surface treatment that provides a protective coating to the scaffolding system.

Powder Coated is a surface treatment that provides a protective coating to the scaffolding system.

Painting is a surface treatment that provides a protective coating to the scaffolding system.

Choosing the Right Scaffolding System

When selecting the right scaffolding system for your construction project, several critical factors must be evaluated to ensure it meets the demands of safety, efficiency, and cost-effectiveness.

1. Project Type and Scaffolding Requirements

Begin by identifying the specific requirements of your construction project. Determine the height, load-bearing capacity, and any unique structural needs that the scaffolding must accommodate. Different projects may require different types of scaffolding, such as frame, system, or suspended scaffolds.

2. Safety Features and Benefits

Safety is paramount in any construction environment. Carefully evaluate the safety features provided by the scaffolding system, including guardrails, slip-resistant surfaces, and secure locking mechanisms. A system that complies with local safety standards and offers robust safety features will reduce risk and ensure worker protection.

3. Cost-Effectiveness and Efficiency

The cost of the scaffolding system should align with your budget without compromising on quality or performance. Consider the initial investment, maintenance, and any hidden costs associated with installation and dismantling. An efficient, easy-to-assemble system will save on labor costs and reduce project delays, making it more cost-effective over time.

4. Adaptability and Versatility

Construction projects often evolve, and a versatile scaffolding system can adapt to changing requirements. Assess the system’s ability to be configured and extended as needed. Scaffolds with modular designs offer more flexibility and can be adjusted to fit various site conditions and project scales, making them suitable for both small-scale and large-scale construction.

5. Surface Treatment and Material Quality

The material quality and surface treatment of scaffolding components play a critical role in durability and safety. Ensure that the scaffolding is made from high-quality materials, such as galvanized or aluminum-coated steel, which resist corrosion and withstand harsh weather conditions. This will extend the lifespan of the scaffolding and reduce maintenance costs over time.

By carefully considering these aspects, you can select a scaffolding system that provides a safe, efficient, and cost-effective solution, ensuring that your construction project progresses smoothly and successfully.

Scaffolding System Safety Guidelines

Ensure that the scaffolding system is erected and disassembled by trained professionals.

Ensure that the scaffolding system is inspected regularly for damage and wear.

Ensure that the scaffolding system is used in accordance with the manufacturer’s instructions.

Ensure that the scaffolding system is equipped with safety features such as guardrails and toe boards.

Ensure that the scaffolding system is used in a safe and stable manner.

Scaffolding System Maintenance and Inspection

Regularly inspect the scaffolding system for damage and wear.

Regularly maintain the scaffolding system to ensure its longevity.

Ensure that the scaffolding system is stored properly when not in use.

Ensure that the scaffolding system is transported safely and securely.

Ensure that the scaffolding system is used in accordance with the manufacturer’s instructions.

Scaffolding System Manufacturer

Selecting the best scaffolding system manufacturer is essential to ensure quality, reliability, and support throughout your construction project. Here are the key factors to consider when choosing a manufacturer:

1. High-Quality Scaffolding Systems

Prioritize a manufacturer known for producing high-quality scaffolding systems. Look for those who use durable materials and advanced manufacturing techniques to create systems that are both safe and long-lasting. High-quality scaffolding will withstand demanding construction environments and reduce the risk of accidents or structural failures.

2. Wide Range of Scaffolding Options

An ideal manufacturer should offer a comprehensive range of scaffolding solutions to meet various project requirements. Whether you need frame scaffolding, system scaffolding, or suspended platforms, a diverse selection allows you to find the best fit for your specific project without compromising on suitability or safety.

3. Excellent Customer Service and Support

Effective customer service is essential in scaffolding manufacturing, as it ensures that you receive timely support, guidance, and answers to technical questions. Look for a manufacturer that is responsive, knowledgeable, and able to provide support before, during, and after the purchase. This includes assistance with installation, troubleshooting, and training for safe usage.

4. Warranty and Product Guarantee

A reliable manufacturer stands behind their products by offering a warranty or guarantee. This demonstrates their commitment to quality and provides you with peace of mind. A warranty protects your investment and ensures that, should any issues arise, repairs or replacements will be covered, minimizing project disruptions and unexpected costs.

5. Certified and Industry-Compliant

Ensure that the manufacturer holds relevant industry certifications and complies with recognized safety and quality standards. Certifications, such as ISO or OSHA compliance, indicate that the manufacturer adheres to strict standards in manufacturing and safety. This is crucial for meeting legal requirements and maintaining safety on site.

By selecting a manufacturer who meets these standards, you ensure that your scaffolding system is safe, dependable, and well-supported, enhancing project efficiency and safety.

Conclusion

System scaffolding is a cost-effective and efficient way to construct scaffolding.

It is a popular choice across the world and in great demand.

System scaffolding is used in various industries, including construction, and is popular across the world.

It is made up of different types of scaffolding, each fulfilling a specific purpose.

System scaffolding is adaptable and can be used in various construction projects, including building and maintenance tasks.