Frame scaffolding

Rapid is the leading frame scaffolding manufacturer and supplier in China, providing customers with industry-leading quality products. Their frame scaffolding systems are designed with durability, functionality, and versatility in mind, allowing users to easily customize the product to their construction and maintenance needs. The frame scaffolding also comes with different accessories, such as poles and couplers, that allow for an even greater degree of customization. Whether you need frame scaffolding for commercial or residential projects, Rapid has a system that will meet your requirements. Contact them today if you have any frame scaffolding inquiries; they look forward to assisting you further!

Rapid Frame Scaffolding Video

Why Rapid?

• Customized standards to meet the specific needs of any work site

• Commitment to safety and durability in all products

• Innovation in design for a better customer experience

• Scaffold services available 24 hours/day, 7 days a week

• Accreditation from EN10901 and ISO3834 for quality assurance

• Certified as work-safe and compliant with all scaffold regulations

• Wide variety of scaffolds available in different sizes to suit all needs

• Comprehensive training provided on how to use the scaffolds safely

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Rapid scaffolding has rich experience and advanced automatic equipment, which can provide scaffolding customized production to meet different needs.

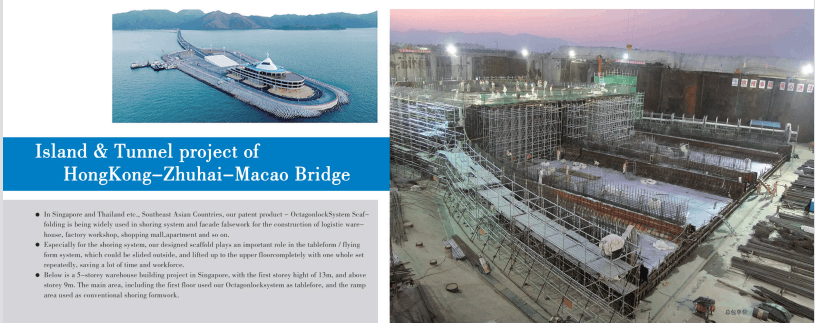

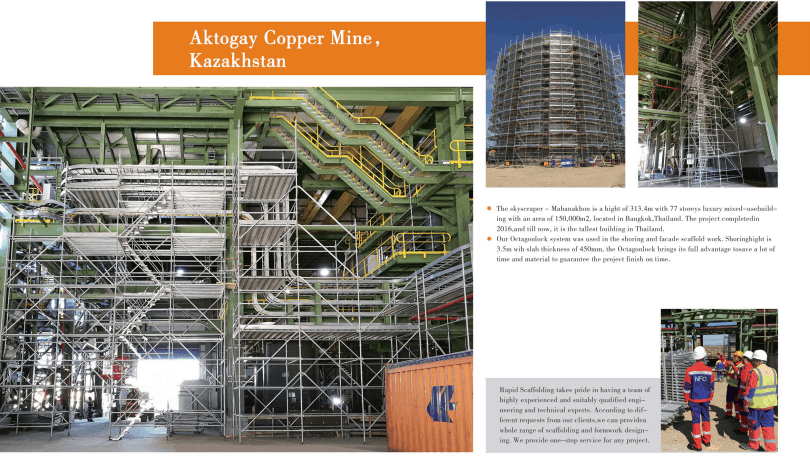

Rapid represent the safety and qualified scaffolding via our construction projects.

Feel the Quality via our products. We improve them always.

There are three kinds of frame scaffolding in our experience along with our customers, such as American Frame, Euro Frame, and Japanese Frame. There are other specific names of frame scaffolding in this industry, like baker scaffolding that is actually narrow frame scaffolding, if you add caster on it, you can move it easily, known as portable scaffolding or rolling scaffolding in some areas.

Following, we list some common data of frame scaffolding. The frame is made in a wide variety of sizes and configurations, and we can meet customer’s requirements in width, height, OD, thickness, etc. Meanwhile, we also supply the steel and aluminum plank, casters to satisfy customer’s applications.

American Frame Scaffolding

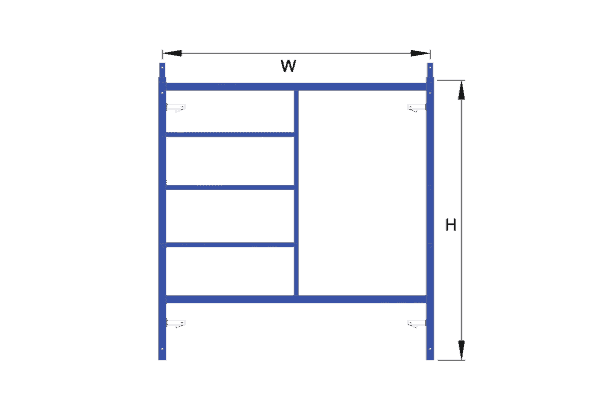

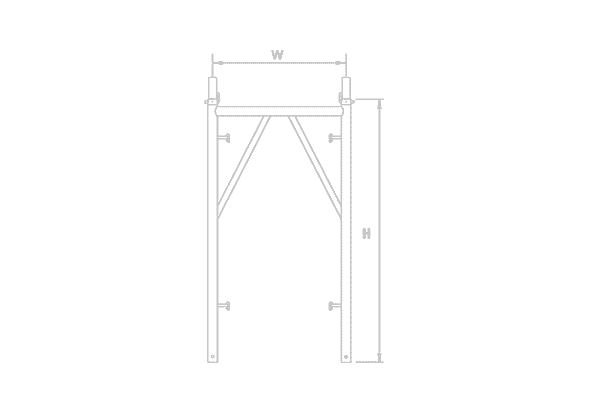

Step Frame

Step Frame, also called Mason Frame

Leg Tube: OD41.2mm, Surface treatment: Powder Coated

Product | Width | Height | |||

Code | Description | Inches | Meters | Inches | Meters |

AFSF01 | 5’*3′ Step Frame | 60 | 1.524 | 36 | 0.914 |

AFSF02 | 5’*4′ Step Frame | 60 | 1.524 | 48 | 1.219 |

AFSF03 | 5’*5′ Step Frame | 60 | 1.524 | 60 | 1.524 |

AFSF04 | 5’*6’4″ Step Frame | 60 | 1.524 | 76 | 1.93 |

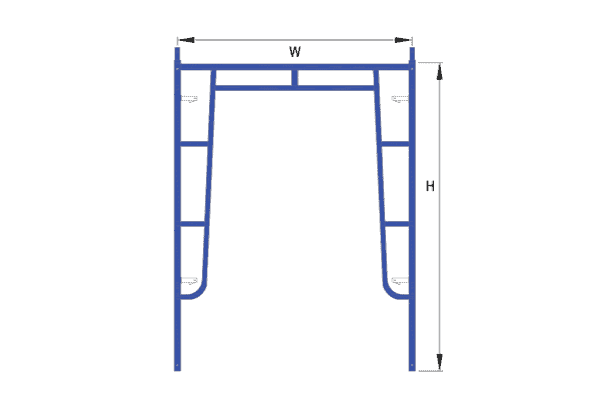

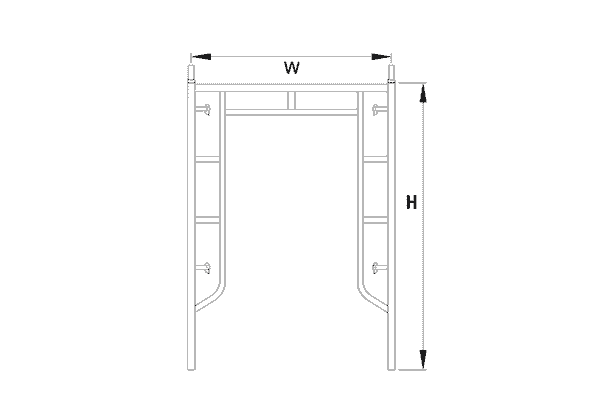

Walk Through Frame

Leg Tube: OD41.2mm, Surface treatment: Powder Coated

Product | Width | Height | |||

Code | Description | Inches | Meters | Inches | Meters |

AFWTF01 | 4’*5’7″ Walk Through Frame | 48 | 1.219 | 67 | 1.702 |

AFWTF02 | 4’*6’4″ Walk Through Frame | 48 | 1.219 | 76 | 1.93 |

AFWTF03 | 5’*4′ Walk Through Frame | 60 | 1.524 | 48 | 1219 |

AFWTF04 | 5’*6’4″ Walk Through Frame | 60 | 1.524 | 76 | 1.93 |

AFWTF05 | 5’*6’7″ Walk Through Frame | 60 | 1.524 | 79 | 2.007 |

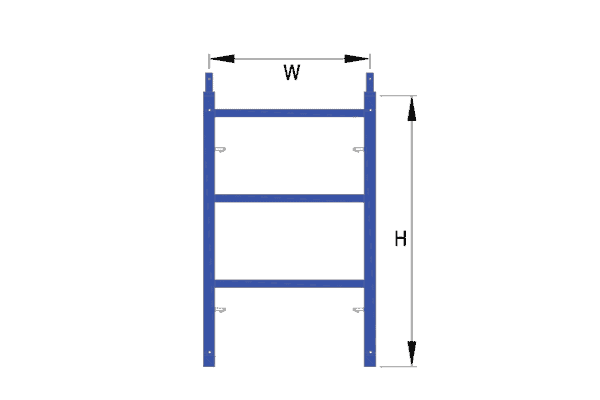

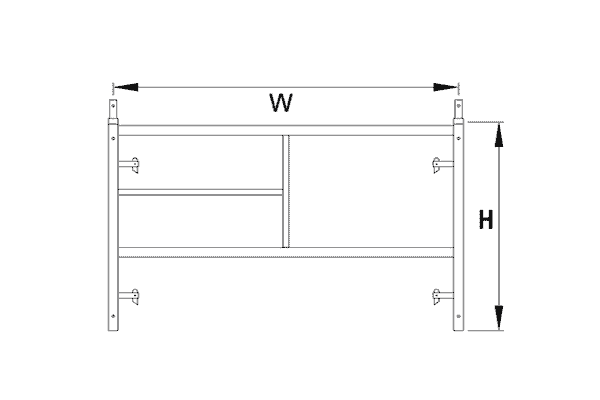

Ladder Frame

Leg Tube: OD41.2mm, Surface treatment: Powder Coated

Product | Width | Height | |||

Code | Description | Inches | Meters | Inches | Meters |

AFLF01 | 2’*5′ Ladder Frame | 24 | 0.61 | 60 | 1.524 |

AFLF02 | 2’*6’4″ Ladder Frame | 24 | 0.61 | 76 | 1.93 |

AFLF03 | 3’*4′ Ladder Frame | 36 | 0.914 | 48 | 1219 |

AFLF04 | 3’*5′ Ladder Frame | 36 | 0.914 | 60 | 1.524 |

AFLF05 | 3’*6′ Ladder Frame | 36 | 0.914 | 72 | 1.829 |

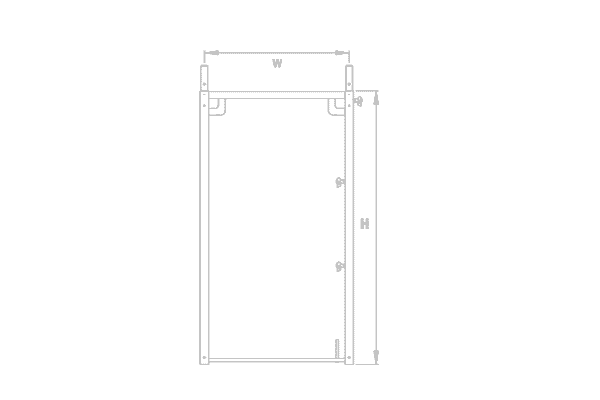

Japanese Frame Scaffolding

Japanese Frame – 01

Surface treatment: Hot-dip Galvanized

Code | Width | Height |

JF01 | 410mm | 1700mm |

JF02 | 610mm | 1700mm |

Japanese Frame – 02

Surface treatment: Hot-dip Galvanized

Code | Width | Height |

JF03 | 1219mm | 1524mm |

JF04 | 1219mm | 1700mm |

JF05 | 1219mm | 1930mm |

Japanese Frame – 03

Surface treatment: Hot-dip Galvanized

Code | Width | Height |

JF06 | 1219mm | 914mm |

JF07 | 1219mm | 1219mm |

Euro Frame Scaffolding

Euro Assembly Frame

Euro Assembly Frame | ||

FINISH: Hot-dip Galvanized | ||

ITEM NO. | W | H |

RSEF 01 | 2’5”(0.73m) | 3’3”(1.0m ) |

RSEF 02 | 2’5”(0.73m) | 6’7”(2.0m) |

Aluminium Robust Hatch-type | ||

FINISH: Plywood & Aluminum | ||

ITEM NO. | W | L |

RSRH 01 | 0.61m | 2.57m |

RSRH 02 | 0.61m | 3.07m |

Frame Scaffolding – The Ultimate FAQ Guide

Frame scaffolding is one of the simplest, easiest, and probably most-sought-after scaffolding systems in the industry because of its overall simplicity. Although there are a lot of contenders in the field of pre-fabricated scaffolding alone, frame scaffolds might just be what your business needs to excel from being on the ground, up!

So, in this article, we’ll elaborate on the idea revolving around frame scaffolding, as we’ll discuss it directly from what it is, where you can get them, how they’re erected, and many more!

What is Frame Scaffolding?

In the simplest, fastest way to put it, frame scaffolding is a versatile and widely-used modular scaffolding system. It’s usually comprised of a combination of vertical and horizontal frames that form a solid, stable structure for workers and materials.

The vertical frames that are connected by cross braces create a ladder-like configuration, elevating the platform or the workplace. Then, the horizontal frames, known as bearers, provide support for platforms.

Because of the “already-built” components, they’re easy to erect and establish! We’ll get to that part of the discussion more as we go on.

Here’s a video from Southwest Scaffold, working on a frame scaffolding structure:

https://youtu.be/7emvHVbfPn8?si=Yw0BHKRnhKkNDTjr

Frame Scaffolding Parts

If you’ve heard of ringlock and cuplock scaffolding, then you would easily be able to know and identify frame scaffolding parts, because, they’re pretty similar. However, for the benefit of everyone, we’ve listed the parts and components of frame scaffolding:

Frames

They’re the structures that allow frame scaffolds to exist. They’re the combination of horizontal and vertical components tied up together and are responsible for the overall integrity of the scaffolding system.

Platforms or Decks

These are the surfaces or the entire area where materials are being held or what workers use to access different parts of the scaffold. They vary in size, but they’ll usually be within the measurement of the frames.

Cross or Diagonal Braces

They’re the component that’s connected to the frames in order to make sure that they don’t wobble. Diagonal braces or crosses ensure that the structural integrity is kept safe, secure, and stable to work with.

Bearers

These are the horizontal beams or the ledgers that run and go through the length of the scaffolding structure.

Screw Jacks

They’re the parts or components that are adjustable. Their main purpose is to allow adjustments on the scaffolding system and help stabilize the scaffold.

Base Plates

These work and operate as the foundation or the bases of the scaffolding systems. They’re there for the overall stability of the scaffolding and to ensure that it will hold a single position.

Pins, Clips, and Fasteners

Last, but most definitely not the least are the pins, clips, and fasteners. These are the components that are responsible for making sure that every component is locked, clipped, and fastened correctly, preventing further problems that can lead to accidents.

These are the primary components of frame scaffolding systems and structures, but, they’re not everything! So, don’t have the misconception that these are the only parts and components you should keep your eyes on.

What Are the Types of Framed Scaffolding?

The primary types of framed scaffolding include single frame and double frame scaffolding systems. Single frame scaffolds are those that are erected and are built only on one side, with the other side using the structure as support.

Double frame scaffolds, on the other hand, are those that are erected to stand independently.

Frame scaffolding falls under supported scaffolding because its components are pre-fabricated. Meaning, everything is already done and produced even before the project starts.

https://youtu.be/eTTLNEVCm-Y?si=W2wJ25m3fDsGdFwp

What is H-Frame Scaffolding?

H-frame scaffolding is a type of scaffolding system where the platform used for a very specific purpose – for working on interior walls and other minor things in construction, such as interior ship repairs, cladding, painting, and insulation.

It’s called h-frame scaffolding because when you look at it, its overall structure forms the letter “H.” H-frame scaffolding systems may not be as tall and long as other scaffolding types because it’s not intended to be used for heavy-duty construction.

What is A-Frame Scaffolding?

A-frame scaffolding, on the other hand, is a scaffolding type that forms the letter “A,” instead of the letter “H,” unlike H-frame scaffolding. Like H-frame scaffolds, A-frame scaffolding systems are used for the purpose of interior designing, painting, as well as repairing of interior parts of properties.

Both H and A-frame scaffolding structures are flexible and versatile to the extent that they’re able to hold a lot of weight and can be used in a wide library of applications and business industries.

What is the Size of A-Frame Scaffolds?

The sizes of A-frame scaffolding systems vary, but the standard would be 2’ or 3’ in width, and about 3’, 4’, 6’, or 8’ high. This, however, is still dependent on the application you’re going to be using A-frame scaffolds for.

H-Frame Scaffolding Size

According to global resources, the standard height of H-frame scaffolds run from a minimum of about 400mm to a 3.0m maximum. However, the most popular and most standard heights would be:

- 914mm

- 1219mm

- 1524mm

- 1700mm

- 1930mm

- 2500mm

A-Frame and H-Frame Scaffolding Price: How Much Do They Cost?

A-frame and H-frame scaffolding may have a lot of differences with each other, but one thing they are closely related on is their overall similarities when it comes to the pricing and budget. When you take a look at how much they are in marketplaces, you’ll see that they cost almost the same.

Their components, which are usually made with galvanized steel, may cost around $12 and $30. If you’re looking for a completed and assembled frame scaffolding, though, it runs from $100 for the simplest ones to $1000, and even $5000 for the best and highest-quality ones.

Here’s the average price from Made-In-China!

Advantages of Framed Scaffolds

The advantages and benefits of framed scaffolds are among their best and most notable selling points. So, here are some of the most notable ones:

Fast and Easy Assembly

So far, one of the best and most notable advantage frame scaffolds have, is that they are quick and easy to install. Because of the simple components they have, it’s easy to ensure that all parts and components are complete and befit the application they’re looking for.

This simplicity of assembly increases productivity and decreases labor time, making them an excellent alternative for time-sensitive construction projects.

Versatile and Compatible

Frame scaffolds are easily adjustable and modifiable to accommodate a big array of job site needs. They can be used in different shapes, forms, and sizes. Thanks to their modular form, they can easily adapt and are efficient for building and construction demands.

Affordable and Cost-Effective

Because to their basic form and ease of manufacture, frame scaffolds are more often cheaper and more cost-effective than their contenders. This assembly overall contributes to total cost reductions, making them an eye-catching and attractive option for low-budget building projects.

Accessible

Walk-through frames provide many access points, which allows workers to effortlessly enter and exit the scaffold. This feature enhances the safety and efficiency of the scaffolding system by shortening the time and effort necessary to access various work zones, compared to other scaffolding structures that have a lot of access points.

Stable and Secure

And to conclude the benefits, frame scaffolding structures are safe, secure, and stable. Frame scaffolds ladder frames, in particular, provide exceptional stability and high load-bearing capability.

What this sturdy design provides is a safe platform for workers and supplies, allowing them to be used and be well-suited for a variety of construction operations, including heavy-duty applications.

Disadvantages of Framed Scaffolds

If you think that frame scaffolds are all rainbows and butterflies, think again. Like many other, there are also a couple of things that you want to consider before going with them.

Less Adaptability to Irregular Structures

When adapting to unconventional building forms or constructions, frame scaffolds may meet accommodation challenges and difficulties. Their overall modular design may not exactly fit into unique and unorthodox sites and projects easily.

Overloading Possibility

Although frame scaffolding systems are recognized for their overall stability, there’s a huge risk of overload, especially if they’re not used with the manufacturer’s instructions. There needs to be a list of careful assessment of load capabilities and respect to safety requirements are essential.

Limited Height Adjustability

When compared to other scaffolding systems, frame scaffolds may have height adjustment constraints. This might be a disadvantage while working on projects that need to change the level of elevation, as more equipment may be required for corrections.

Transportation Limits

While frame scaffold components are simple to install, transportation may take its toll and can be a lot more challenging and difficult. This can result in higher and more expensive transportation expenses and logistical risks, specifically when operating in congested regions.

Why Rapid Scaffolding is Your Best Bet For Frame Scaffolding

Besides the fact that we’ve delved down the industry for more than two decades, our lineup of engineers, experts, and scaffolding operators are always fresh and hungry for achievements. We’ve held a consistent place at the top of the scaffolding and formwork ladder through sheer competence, dedication, and a constant drive for innovation.

We take pride in the excellent-quality scaffolds and formwork we offer in the market. From the simplest of generalized modular scaffolding, ringlock scaffolding, to HAKI or Kwikstage scaffolding, we’ll get you what you need!

Conclusion

Rapid Scaffolding is the permanent solution to your temporary elevation and access problems. Our entire team takes pride on the amount of dedication and projects we’ve completed in 20+ years of being the best and the top formwork and scaffolding manufacturer and provider in the country.

Don’t hesitate to give us a ring if you want to dive deep into the details of all our offers! Reach out to us and we’ll be more than happy to send a free quotation to you!

Contents

- Rapid Frame Scaffolding Video

- Why Rapid?

- American Frame Scaffolding

- Step Frame

- Walk Through Frame

- Ladder Frame

- Japanese Frame Scaffolding

- Japanese Frame – 01

- Japanese Frame – 02

- Japanese Frame – 03

- Euro Frame Scaffolding

- Euro Assembly Frame

- Frame Scaffolding – The Ultimate FAQ Guide

- What is Frame Scaffolding?

- Frame Scaffolding Parts

- Frames

- Platforms or Decks

- Cross or Diagonal Braces

- Bearers

- Screw Jacks

- Base Plates

- Pins, Clips, and Fasteners

- What Are the Types of Framed Scaffolding?

- What is H-Frame Scaffolding?

- What is A-Frame Scaffolding?

- What is the Size of A-Frame Scaffolds?

- H-Frame Scaffolding Size

- A-Frame and H-Frame Scaffolding Price: How Much Do They Cost?

- Advantages of Framed Scaffolds

- Fast and Easy Assembly

- Versatile and Compatible

- Affordable and Cost-Effective

- Accessible

- Stable and Secure

- Disadvantages of Framed Scaffolds

- Less Adaptability to Irregular Structures

- Overloading Possibility

- Limited Height Adjustability

- Transportation Limits

- Why Rapid Scaffolding is Your Best Bet For Frame Scaffolding

- Conclusion

- Get A Quote Now !