Octagonlock Scaffolding

Octagonlock scaffolding is an efficient and versatile system used around the world and Rapid is the top Octagonlock scaffolding manufacturer and supplier in China. With quality materials, efficient production techniques, and excellent customer service, Rapid has earned a reputation as one of the most reliable Octagonlock scaffolding suppliers in the industry. Whether your project requires Octagonlock systems for construction sites or any other purpose, Rapid provides Octagonlock systems that are robust enough to meet construction standards. If you have specific requirements for Octagonlock scaffolding, give us a call today—we’d love to help you get exactly what you need!

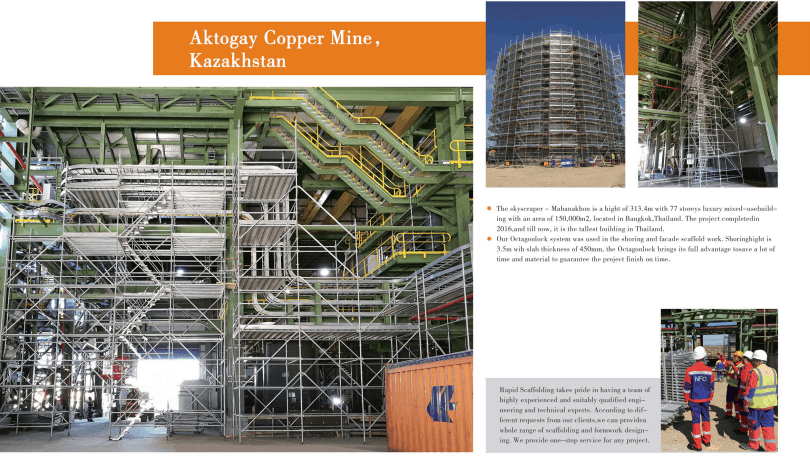

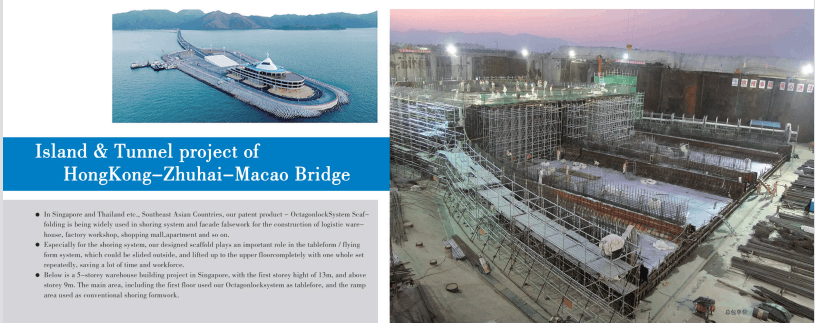

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Rapid scaffolding has rich experience and advanced automatic equipment, which can provide scaffolding customized production to meet different needs.

Rapid represent the safety and qualified scaffolding via our construction projects.

Feel the Quality via our products. We improve them always.

Rapid Octagonlock Scaffolding Video

Specification:

| Octagonlock Standard | |||||||

| FINISH:Hot-dip Galvanize | |||||||

| We have two options based on customer’s needed load capacity, which are | |||||||

| 1. Light duty: | |||||||

| ITEM NO. | MATERIAL | L | WEIGHT APPROX. | ||||

| RSOS 050 | Q355 48.3 X 3.2mm | 0.5m | 3.07kg | ||||

| RSOS 100 | Q355 48.3 X 3.2mm | 1.0m | 5.54kg | ||||

| RSOS 150 | Q355 48.3 X 3.2mm | 1.5m | 8.01kg | ||||

| RSOS 200 | Q355 48.3 X 3.2mm | 2.0m | 10.48kg | ||||

| RSOS 250 | Q355 48.3 X 3.2mm | 2.5m | 12.95kg | ||||

| RSOS 300 | Q355 48.3 X 3.2mm | 3.0m | 15.42kg | ||||

| 2. Heavy duty: | |||||||

| ITEM NO. | MATERIAL | L | WEIGHT APPROX. | ||||

| RSHS 050 | Q355 60.3 X 3.2mm | 0.5m | 3.84kg | ||||

| RSHS 100 | Q355 60.3 X 3.2mm | 1.0m | 6.91kg | ||||

| RSHS 150 | Q355 60.3 X 3.2mm | 1.5m | 9.99kg | ||||

| RSHS 200 | Q355 60.3 X 3.2mm | 2.0m | 13.18kg | ||||

| RSHS 250 | Q355 60.3 X 3.2mm | 2.5m | 16.29kg | ||||

| RSHS 300 | Q355 60.3 X 3.2mm | 3.0m | 19.21kg | ||||

Octagonlock Scaffolding – The Complete FAQ Guide

Have you ever heard of what an octagonlock scaffolding is? It could sound new even to experienced scaffolding experts, so, in this guide, we’ll go ahead and discuss all the things you need to know and learn about octagonlock scaffolding from start to finish!

We’ll take a look at what it is, where they’re used, and why they’re considered one of the common types of scaffolding systems in the building and construction.

What is Octagonlock Scaffolding?

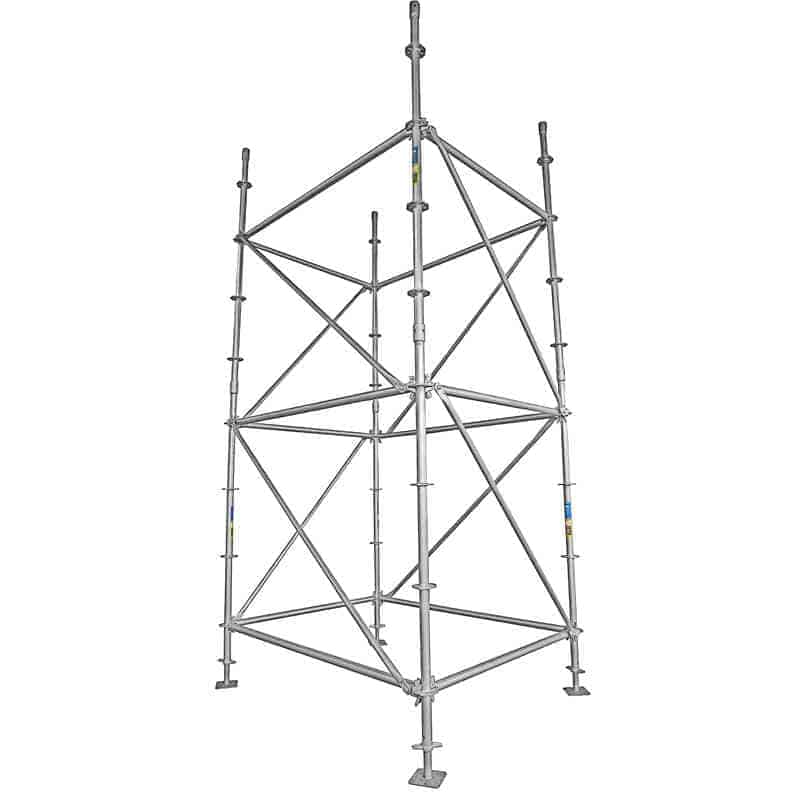

Octagonlock scaffolding is one of the newer and more advanced types of scaffolding systems. From the term alone, it’s a kind of lock scaffolding that uses an “eight-hole” system, all of which perfectly fit the ledgers and diagonal heads, making it straight and stable.

Because it is a type of ringlock scaffolding system, it’s being widely used by a lot of construction, architectural, engineering, and contractor businesses worldwide.

Is Octagonlock Scaffolding a Type of Ringlock Scaffolding?

Yes, an octagonlock system falls under the category of ringlock scaffolding because it uses a lock that has eight holes on the rosette, which is designed to allow varying positions when they’re clamped and locked with each other.

https://youtu.be/FaVjI6wAkug?si=pXYD6JuFi4pNHN2P

What Are Octagonlock Scaffold Systems Made Of?

In a typical sense, octagonlock scaffolding systems are made with high-quality galvanized steel. So, the main material is steel tubing as it’s known for its brute strength, excellent durability, and high resistance to various chemical and environmental conditions.

These tubes are precisely shaped to form the octagonal framework, complete with eight holes, offering stability and support to hold the entire scaffolding structure.

What Scaffolding Uses Locking Ring Connectors

Evidently, the scaffolding system that uses locking ring connectors and similar types of connection is ringlock scaffolding. Furthermore, ringlock scaffolding is supplemented by ledger ends and locking pins to ensure that the connections are rigid and aren’t wobbly.

To conclude, octagonlock scaffolding, which falls under the category of ringlock scaffolding, also uses locking ring connectors. The difference is that these octagonal locks that octagonlock scaffolds use contain eight different holes.

Ringlock Scaffolding Dimensions

The dimensions and measurements of ringlock components vary from one scaffolding system to another. However, like with us here at Rapid Scaffolding, we’re able to offer custom-made ringlock scaffolding components and equipment for you.

To give an average, though, here’s a list we’ve sourced and gathered out from various sources:

Vertical Standards (Uprights):

These are the beams that run vertically. They go up and down, providing the height that the scaffolding system is looking for.

- Length: Typically ranges from 3 to 5 feet (0.91 to 1.52 meters)

- Diameter: Commonly around 2 inches (5.08 centimeters)

Horizontal Ledgers (Runners)

The opposite of verticals. They go from left to right, dictating the width and length of the structure.

- Length: Usually varies from 4 to 10 feet (1.22 to 3.05 meters)

- Diameter: Typically around 1.5 inches (3.81 centimeters)

Diagonal Braces (Cross Braces)

Diagonal braces are the added support to the standard-ledger combination. A cross brace adds stability for the structure not to sway.

- Length: Generally falls between 7 to 10 feet (2.13 to 3.05 meters)

- Diameter: Similar to horizontal ledgers, around 1.5 inches (3.81 centimeters)

Steel Planks or Platforms

Last but most definitely not least are the platforms. They’re the working area within the scaffolding system. It’s where workers walk on or materials are placed.

- Width: Typically 9 to 12 inches (22.86 to 30.48 centimeters)

- Length: Varies, but commonly 7 feet (2.13 meters)

- Thickness: Typically around 1.5 inches (3.81 centimeters)

NOTE: These are only general estimates and not exact ones. It’s important to note that not all these measurements are accurate and precise, and that it will vary from one manufacturer to another.

How Much Does Octagonlock Scaffolding Cost?

Like other scaffolding systems, the cost of Octagonlock scaffolding systems vary based on different factors that make up what it is. This can be anything from the supplier, specifications and measurements of the components, and geographical location of the manufacturer.

If we were to look at the average, according to recent data from online platforms like Made-In-China and Alibaba, you can expect the price for Octagonlock scaffolding components to range from approximately $20 to $50 per piece.

NOTE: It’s important to note that this is only a general estimate. The specific prices may depend on the supplier, the overall quantity of the components purchased, as well as additional features or customization options.

How Are Octagonlock Scaffolds Erected?

The erecting or establishment of these octagonlock scaffolding systems is not far from the traditional way of setting up ringlock scaffolds. In fact, here’s an overview of the process of erecting or setting an octagonlock scaffold!

Step #1: Foundation Preparation

The first step is usually the hardest, and that is true for octagonlock scaffolding systems, too. By ensuring a stable and level foundation for the Octagonlock scaffold, every component is inspected and checked to be at their best and pristine condition.

As for the area, you’ll want to make sure that it’s clear of any debris or obstacles that could compromise the setup.

Step #2: Base Installation

Then, the next step would be to install the base plates on the prepared and planned foundation. You’d want to attach the vertical standards (uprights) to the base plates, making sure that they’re secured in an octagonal formation.

These vertical standards serve as the main support for the overall scaffold structure and integrity.

Step #3: Ledger Connection

For the next step, you’ll have to link and connect the horizontal ledgers to the vertical standards in conjunction to one another. To visualize it, the ledgers will be the ones forming the outer edges of the octagon.

Be sure to lock the mechanisms or pins provided by the Octagonlock system by ensuring a sure fit.

Step #4: Diagonal Bracing

Install diagonal braces between the chosen and erected vertical standards. What these braces will do is reinforce the entire structure, preventing lateral movement and adding overall integrity and rigidity to the structure. Make sure that you’ll connect the braces securely to the vertical standards.

Step #5: Platform Installation

Once done, the next step would be to place the scaffold planks or platforms on the ledgers to create a safe working surface for construction or maintenance activities.

Lock the platforms securely and tighten them up with each ledger to be 100% sure that everything and everyone is safe on the platform.

Step #6: Continued Vertical Build

Continue building the scaffold vertically upright by adding a combination of vertical standards and ledgers. Just be sure that the octagonal configuration is maintained.

Leverage and make use of the locking mechanisms at each connection point to ensure stable and secure systems and structures.

Step #7: Guardrail Installation

Attach guardrails to the scaffold at the correct height to make sure of the safety of the workers. Ensure that the guardrails are fastened properly and that meet safety standards.

Step #8: Final Inspection

Last but most definitely not least would be to go through a comprehensive and thorough inspection of the erected Octagonlock scaffold. Check and observe all connections, platforms, locks, and clamps to ensure that they’re secure and that they meet the industry’s standards.

Make any necessary adjustments to guarantee the scaffold’s stability and overall safety.

That’s the process of erecting an octagonal scaffolding system. As you may have noticed, they don’t fall far from how ringlock scaffolding systems are erected and built!

Octagonlock vs. Cuplock Scaffolding Systems

Octagonlock and cuplock scaffolding systems are considered two of the newest innovative scaffolding systems in the industry.

Characteristic or Feature | Cuplock Scaffolding System | Octagonlock Scaffolding System |

Structure and Design | The structure boasts of circular vertical standards with cup-like connectors. | The structure is octagonal or octagon-shaped. |

Cost | Moderate cost and relatively easy to source out and get. | Price ranges vary, but they typically fall under the costly and expensive category. |

Utility | Simple and easy to utilize because of the cuplock feature. Most of the components fit with one another easily. | Extremely easy usage and erection. Everything is pre-fabricated and can fit in multiple angles and applications. |

Connection Type | Uses captive mobile nodes that slide down, securing ledgers and guaranteeing fast erection. | Uses lockring connections that ensures safe and secure connections. |

Versatility | Configurations are flexible and are highly adaptable to many different types of sites and structures. | Can be used in a wide library of tasks and projects. Offers guaranteed stability. |

Applications | Usual application involves building construction, renovation, and infrastructure projects | Widely used in different types of construction, maintenance, and industrial projects. |

Where to Get Octagonlock Scaffolds?

If there is one scaffolding system that is not the favorite or the most popular, it would be octagonlock scaffolding. And while it’s not the most famous, it’s one of the best in the eyes of the construction businesses and contractors who know about it.

Check this Octagonlock scaffolding offer from Alibaba out.

You’ll most likely find octagonlock scaffolds from scaffolding formwork and design experts and manufacturers that offer ringlock scaffolding systems. There are a lot of options out there, but here in China, no other scaffolding manufacturer has been trusted but us here at Rapid Scaffolding.

For 2 decades and counting, we’ve produced top-quality and the best octagonlock scaffolding systems for contractors and construction businesses in and outside the country.

Why Rapid Scaffolding is the Best Choice For Octagonlock Scaffolding Systems

Rapid Scaffolding is a team of experts and dedicated professionals in the scaffolding industry. Our legacy remains one of the models of scaffolding manufacturing in the country. We can manufacture custom-made octagonlock scaffolding systems, from the structures with the simplest

Employed with seasoned and experienced workers and operators, you can come to us with all the octagonlock scaffolding systems you need. Reach out to us and we’ll be more than happy to help you out in manufacturing the scaffolding structure that you need!

Our skillset and strategies aren’t only limited to octagonlocks scaffolding. You can also count on us if you need help with other scaffold types, such as Kwikstage scaffolding, HAKY scaffolding, or aluminum scaffolding!

Contact us and get a free estimate of the scaffolding system you want and need!

Contents

- Rapid Octagonlock Scaffolding Video

- Octagonlock Scaffolding – The Complete FAQ Guide

- What is Octagonlock Scaffolding?

- Is Octagonlock Scaffolding a Type of Ringlock Scaffolding?

- What Are Octagonlock Scaffold Systems Made Of?

- What Scaffolding Uses Locking Ring Connectors

- Ringlock Scaffolding Dimensions

- Vertical Standards (Uprights):

- Horizontal Ledgers (Runners)

- Diagonal Braces (Cross Braces)

- Steel Planks or Platforms

- How Much Does Octagonlock Scaffolding Cost?

- How Are Octagonlock Scaffolds Erected?

- Step #1: Foundation Preparation

- Step #2: Base Installation

- Step #3: Ledger Connection

- Step #4: Diagonal Bracing

- Step #5: Platform Installation

- Step #6: Continued Vertical Build

- Step #7: Guardrail Installation

- Step #8: Final Inspection

- Octagonlock vs. Cuplock Scaffolding Systems

- Where to Get Octagonlock Scaffolds?

- Why Rapid Scaffolding is the Best Choice For Octagonlock Scaffolding Systems

- Get A Quote Now !