Ringlock Scaffolding

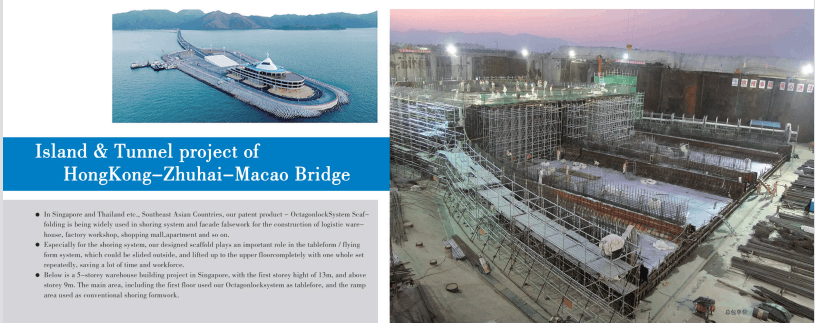

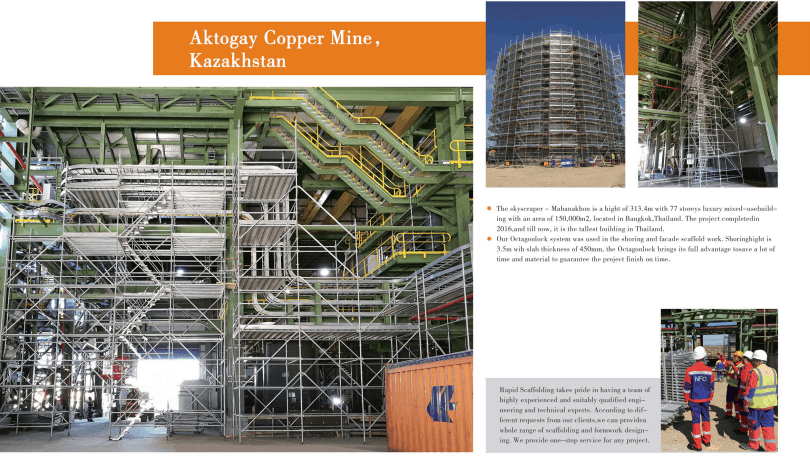

Rapid is one of the leading ringlock scaffolding manufacturers and suppliers in China. With its decades of experience in ringlock production, Rapid offers its customers only the best ringlock systems available. Whether you are looking for a system for a construction project or to use for light-duty scaffolding, Rapid ensures quality and innovation in all ringlock products. If you have any requirements for ringlock scaffolding, Rapid guarantees complete customer satisfaction and an unparalleled commitment to customer service. Contact them today to learn more about ringlock systems and discover how they can help fulfill your ringlock needs!

Rapid Ringlock Scaffolding Video

Why Rapid?

• High quality scaffolding at competitive price

• Customized standards to meet the specific needs of any work site

• Commitment to safety and durability in all products

• Innovation in design for a better customer experience

• Scaffold services available 24 hours/day, 7 days a week

• Accreditation from EN 1090, EN 12811 and EN 3834 for quality assurance

• Certified as work-safe and compliant with all scaffold regulations

• Wide variety of scaffolds available in different sizes to suit all needs

• Comprehensive training provided on how to use the scaffolds safely

3D Model Of Ringlock Scaffolding

In modern construction and engineering projects, the Ringlock scaffolding system is widely recognized for its efficiency, safety, and flexibility. To help our clients better understand and plan their projects, we offer 3D models of Ringlock scaffolding, providing you with a visual tool to assist in design and construction.

With our 3D models, you can:

- Accurately visualize the structure: Gain a comprehensive understanding of each component and how they assemble, ensuring thorough planning before construction.

- Save time and costs: Identify potential issues in advance through the virtual model, reducing on-site adjustments and construction errors.

- Increase efficiency: Quickly generate design plans for various project scales and easily simulate different configurations.

- Enhance team collaboration: Share with engineers, designers, and construction teams to ensure everyone is aligned on the project details.

Our Ringlock 3D models are based on industry-standard dimensions and configurations, allowing you to adjust according to your project’s specific needs, ensuring a perfect fit.

Click to explore our Ringlock scaffolding 3D models and bring a more efficient, visual construction solution to your project!

Ringlock Scaffolding Components

Ringlock diagonal brace

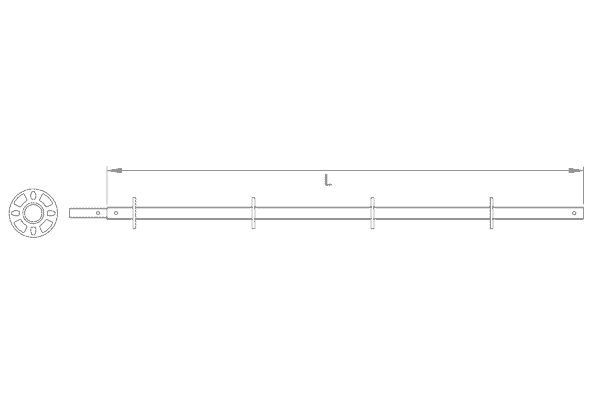

Allround ringlock scaffolding standard

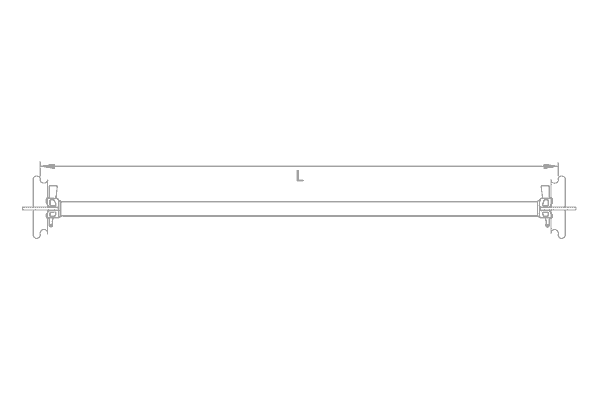

Allround ringlock scaffold doubler ledger

Ringlock side bracket

Ringlock ladder bracket

Ringlock ladder

Ringlock stair

ledger end

Rinlock Wedge

Lattice Girder

Allround ringlock scaffolding base collar

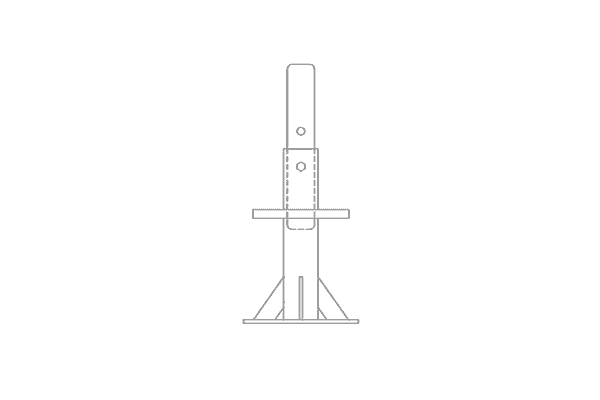

Scaffolding U head screw jack

Scaffolding base jack

Allround ringlock scaffolding steel plank,steel deck

Ringlock scaffolding plank

| Ringlock Standard | |||||||

| FINISH:Hot-dip Galvanize | |||||||

| ITEM NO. | MATERIAL | L [m] | WEIGHT APPROX. [kg] | ||||

| RSRS 050 | Q355 48.3 X 3.2mm | 0.5 | 3.09 | ||||

| RSRS 100 | Q355 48.3 X 3.2mm | 1.0 | 5.52 | ||||

| RSRS 150 | Q355 48.3 X 3.2mm | 1.5 | 7.95 | ||||

| RSRS 200 | Q355 48.3 X 3.2mm | 2.0 | 10.38 | ||||

| RSRS 250 | Q355 48.3 X 3.2mm | 2.5 | 12.8 | ||||

| RSRS 300 | Q355 48.3 X 3.2mm | 3.0 | 15.23 | ||||

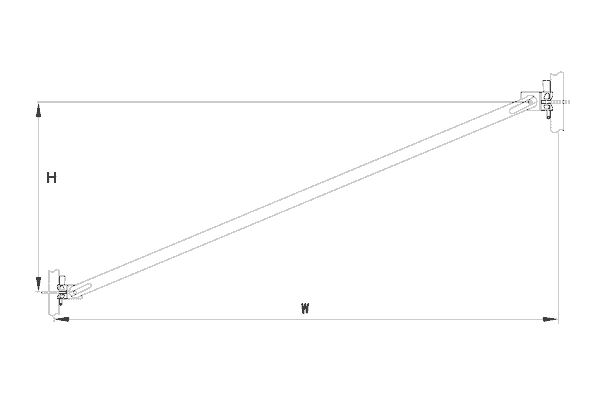

| Ringlock Diagonal Brace | |||||||

| FINISH:Hot-dip Galvanize | |||||||

| ITEM NO. | MATERIAL | W*H [m] | WEIGHT APPROX. [kg] | ||||

| RSRB 2120 | Q235 48.3 X 2.5mm | 0.73*2 | 8.09 | ||||

| RSRB 2230 | Q235 48.3 X 2.5mm | 1.04*2 | 8.4 | ||||

| RSRB 2250 | Q235 48.3 X 2.5mm | 1.09*2 | 8.47 | ||||

| RSRB 2400 | Q235 48.3 X 2.5mm | 1.4*2 | 8.91 | ||||

| RSRB 2490 | Q235 48.3 X 2.5mm | 1.57*2 | 9.2 | ||||

| RSRB 2810 | Q235 48.3 X 2.5mm | 2.07*2 | 10.16 | ||||

| RSRB 3180 | Q235 48.3 X 2.5mm | 2.57*2 | 11.28 | ||||

| RSRB 3580 | Q235 48.3 X 2.5mm | 3.07*2 | 12.49 | ||||

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Rapid scaffolding has rich experience and advanced automatic equipment, which can provide scaffolding customized production to meet different needs.

Rapid represent the safety and qualified scaffolding via our construction projects.

Feel the Quality via our products. We improve them always.

Ringlock Scaffold Specifications:

Ringlock Standard

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q345, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| RLS500 | 1 Ring standard w/spigot | 19.69 | 0.5 |

| RLS1000 | 2 Ring standard w/spigot | 39.37 | 1.0 |

| RLS1500 | 3 Ring standard w/spigot | 59.06 | 1.5 |

| RLS2000 | 4 Ring standard w/spigot | 78.74 | 2.0 |

| RLS2500 | 5 Ring standard w/spigot | 98.43 | 2.5 |

| RLS3000 | 6 Ring standard w/spigot | 118.11 | 3.0 |

Ringlock Ledger

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q345, Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLL073 | 2′-4″ Ledger | 28.82 | 0.73 |

| RLL1090 | 3′-6″ Ledger | 42.83 | 1.09 |

| RLL1290 | 4′-3″ Ledger | 50.63 | 1.29 |

| RLL1570 | 5′-2″ Ledger | 61.88 | 1.57 |

| RLL2070 | 6′-9″ Ledger | 81.5 | 2.07 |

| RLL2570 | 8′-6″ Ledger | 101.3 | 2.57 |

| RLL3070 | 10′-1″ Ledger | 121 | 3.07 |

Ringlock Diagonal Brace

Tube diameter: 48.3mm, thickness: 2.5mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Width | Length | |||

| Code | Description | Inches | Meters | Inches | Meters |

| RLDB2120 | 2′-4″ Diagonal Brace | 28.82 | 0.73 | 78.74 | 2 |

| RLDB2250 | 3′-6″ Diagonal Brace | 42.83 | 1.09 | 78.74 | 2 |

| RLDB2350 | 4′-3″ Diagonal Brace | 50.63 | 1.29 | 78.74 | 2 |

| RLDB2490 | 5′-2″ Diagonal Brace | 61.88 | 1.57 | 78.74 | 2 |

| RLDB2810 | 6′-9″ Diagonal Brace | 81.5 | 2.07 | 78.74 | 2 |

| RLDB3180 | 8′-6″ Diagonal Brace | 101.3 | 2.57 | 78.74 | 2 |

| RLDB3580 | 10′-1″ Diagonal Brace | 121 | 3.07 | 78.74 | 2 |

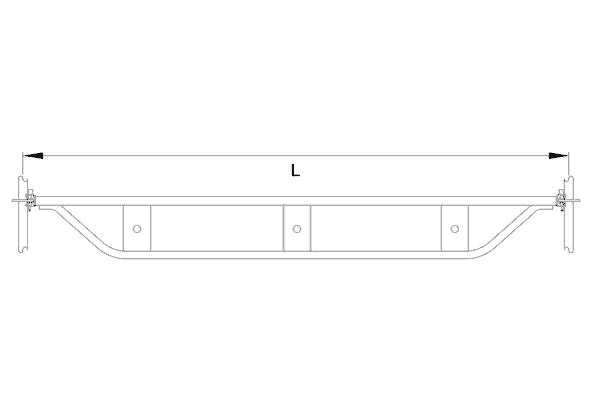

Ringlock Bridge Ledger

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLBL1570 | 5′-2″ Bridge Ledger | 61.88 | 1.57 |

| RLBL2070 | 6′-9″ Bridge Ledger | 81.5 | 2.07 |

| RLBL2570 | 8′-6″ Bridge Ledger | 101.3 | 2.57 |

| RLBL3070 | 10′-1″ Bridge Ledger | 121 | 3.07 |

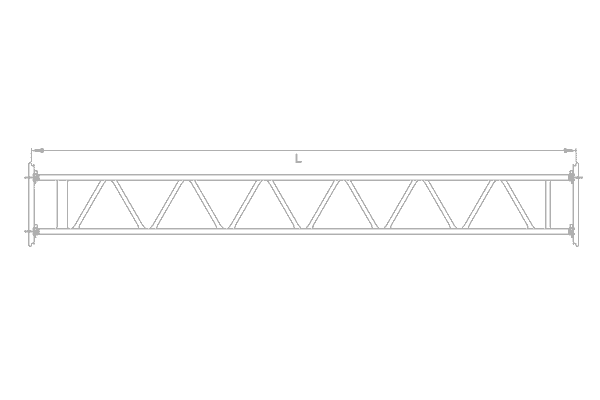

Ringlock Lattice Ggirder

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLLG1570 | 5′-2″ Lattice Girder | 61.88 | 1.57 |

| RLLG2070 | 6′-9″ Lattice Girder | 81.5 | 2.07 |

| RLLG2570 | 8′-6″ Lattice Girder | 101.3 | 2.57 |

| RLLG3070 | 10′-1″ Lattice Girder | 121 | 3.07 |

| RLLG4140 | 13′-7″ Lattice Girder | 163 | 4.14 |

| RLLG5140 | 16′-10″ Lattice Girder | 202.4 | 5.14 |

| RLLG5141 | 20′-2″ Lattice Girder | 242 | 6.14 |

| RLLG5142 | 25′-3″ Lattice Girder | 303.5 | 7.71 |

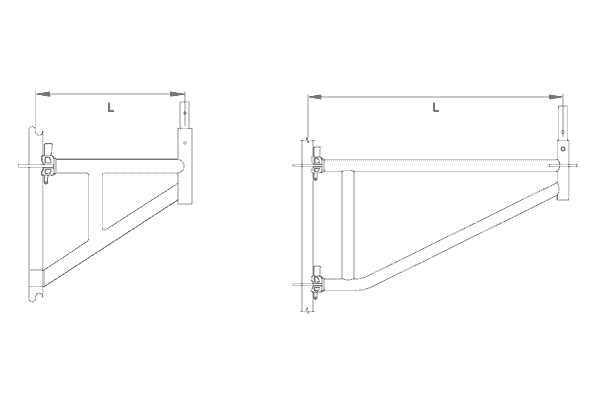

Ringlock Board Bracket

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLBB360 | 1′-2″ Board Bracket | 14.17 | 0.36 |

| RLBB390 | 1′-3″ Board Bracket | 15.35 | 0.39 |

| RLBB730 | 2′-4″ Board Bracket | 28.82 | 0.73 |

| RLBB1090 | 3′-6″ Board Bracket | 42.83 | 1.09 |

Ringlock Base Collar

Tube size: 48.3×3.2mm & 57×2.5mm. Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLBC200 | Base Collar | 7.87 | 0.2 |

Ringlock Caster Adapter

| Product | Length | ||

| code | description | Inches | Meters |

| RLCA300 | Caster Adapter | 12.13 | 0.3 |

Ringlock scaffolding is suitable for:

- Circular and curved structures.

- Straight, rectangular, and square configurations.

- Specially shaped designs.

- Mobile and independent scaffolding towers.

Its adaptability and robust design make it a go-to choice for industrial construction projects.

Advantages of Ringlock Scaffolding

1. Saves Time in Assembly

Ringlock scaffolding reduces erection time significantly compared to traditional tube and clamp systems. For example:

| Scaffold System | Erection Time |

|---|---|

| Tube Clamp System | 321 minutes |

| Ringlock Scaffolding | 151 minutes |

This time efficiency translates into lower labor costs and faster project turnaround.

2. High Versatility

Ringlock scaffolding’s circular rosette with eight connecting points allows simultaneous connections for braces and ledgers. This makes it suitable for:

- Irregularly shaped structures.

- Complex geometries, such as arches or inclined planes.

It provides the same adaptability as tube and clamp scaffolding but with faster and more secure assembly.

3. Superior Load-Bearing Capacity

Ringlock scaffolding outperforms many traditional scaffolding systems in terms of load capacity. For instance:

- A three-tier ringlock scaffold tower at a height of 6.3 meters can support 396.3 KN with 3mm steel.

- Larger diameter ringlock standards (OD 60.3mm) can bear up to 639.1 KN.

These figures make it ideal for heavy-duty applications like shoring and industrial infrastructure projects.

4. No Extra Couplers Required

Each ringlock component has built-in locks and fixed connection points. This eliminates the need for additional couplers or clamps, reducing:

- Loose parts.

- Assembly complexity.

5. Reduced Labor Requirements

The intuitive design of ringlock scaffolding minimizes the need for a large workforce. Components such as vertical standards with fixed locks enable quick installation and dismantling, often with fewer scaffolders.

6. Fewer Accessories

Compared to other systems like cuplock and kwikstage scaffolding, ringlock scaffolding requires fewer accessories:

- Ringlock Standards: Single ring at every 500mm interval.

- Cuplock Standards: Two cups (top and bottom) at every 500mm interval.

- Kwikstage Standards: Four V-clips per interval.

This simplicity not only reduces costs but also simplifies inventory management.

7. Lightweight Design

Ringlock scaffolding components are lighter than cuplock and kwikstage alternatives, making them easier to handle and transport. For instance:

- 1.0m Ringlock Standard: 5.39 kg.

- 1.0m Cuplock Standard: 5.81 kg.

- 1.0m Kwikstage Standard: 6.30 kg.

8. Longevity

Ringlock scaffolding is hot-dip galvanized, offering a lifespan of 15–20 years without rust. This durability ensures:

- Consistent performance across multiple projects.

- Lower maintenance costs compared to painted alternatives.

9. Efficient Transportation and Storage

Ringlock scaffolding components are stackable and can be packed in pallets or racks. This setup allows:

- Easy handling with forklifts.

- Space-saving storage in warehouses.

- Streamlined logistics for long-distance shipping.

10. Minimal Maintenance

Made from high-strength steel or aluminum, ringlock components are resistant to deformation and rust. This durability reduces the need for frequent repairs, further lowering operational costs.

Material and Dimensions

Material Options

- Steel: Hot-dip galvanized steel grades S235 and S355.

- Aluminum: Lightweight 6082-grade aluminum.

Standard Sizes

- Standards (Verticals): From 0.5m to 4.0m.

- Ledgers (Horizontals):

- Europe: 0.73m to 3.07m.

- USA: 2’2” to 10’.

- Planks:

- Europe: 0.73m to 3.07m.

- USA: 0.65m to 3.05m.

Diameter Options

- Standards: OD 48.3mm or OD 60.3mm.

- Ledgers and Transoms: OD 48.3mm.

- Diagonal Braces: OD 48.3mm or OD 42.7mm.

- Base Jacks: OD 38mm or OD 48mm.

Custom sizes are available to meet specific project requirements.

Why Choose Ringlock Scaffolding?

Ringlock scaffolding offers a comprehensive solution for modern construction challenges. Its advantages include:

- Time and labor efficiency.

- High load capacity for demanding projects.

- Durable materials with long service life.

- Reduced costs due to fewer accessories and maintenance needs.

With its versatility and robust performance, ringlock scaffolding is an excellent long-term investment for contractors and construction firms.

For more details on ringlock scaffolding and to explore customization options, contact us today!

Ringlock Scaffolding – The Ultimate FAQ Guide

In the construction and structural industry, ringlock scaffolding has been one of the best and most reliable types of scaffolding in terms of structural integrity. So, if you are looking for reliable ringlock scaffolding for sale or for rent, you’re just in the right guide!

You’ll find a lot of resources online, but most of them aren’t as accurate and precise. In this article, though, we’ll let you in on what ringlock scaffolding is, how they’re used, where they’re used, and why they’re chosen as the choice for scaffolding.

What is a Ringlock Scaffolding?

Ringlock scaffolding is a scaffolding type or classification that’s used in heavy construction and the industrial sector. Known as one of the best, easiest, and fastest erections to assemble, it’s usually installed and assembled using prefabricated components, such as ledgers and rosettes.

It falls under the classification of modular scaffolding because it uses the use of horizontal, vertical, and diagonal components (posts, tubes, and other parts, in particular).

Understanding What a Ringlock Is

For you to understand it better, imagine a ring and a lock that’s joined together. Its strength and integrity are the primary things that are holding the entire vertical structure. The prefabricated parts and components supplement and complement each other, making sure that they don’t just fall off and break down.

Now that we know a ringlock scaffold is a type of modular scaffold, it’s imperative that you know about it, too. Most people, especially those that have been in the business long enough would be aware of what it is.

But, for the benefit of everyone, let’s go ahead and discuss what modular scaffolding really is to the brim!

Be in the know about ringlock scaffolding through this video!

Ringlock scaffolding is suitable for:

- Circular and curved structures.

- Straight, rectangular, and square configurations.

- Specially shaped designs.

- Mobile and independent scaffolding towers.

Its adaptability and robust design make it a go-to choice for industrial construction projects.

Advantages of Ringlock Scaffolding

1. Saves Time in Assembly

Ringlock scaffolding reduces erection time significantly compared to traditional tube and clamp systems. For example:

| Scaffold System | Erection Time |

|---|---|

| Tube Clamp System | 321 minutes |

| Ringlock Scaffolding | 151 minutes |

This time efficiency translates into lower labor costs and faster project turnaround.

2. High Versatility

Ringlock scaffolding’s circular rosette with eight connecting points allows simultaneous connections for braces and ledgers. This makes it suitable for:

- Irregularly shaped structures.

- Complex geometries, such as arches or inclined planes.

It provides the same adaptability as tube and clamp scaffolding but with faster and more secure assembly.

3. Superior Load-Bearing Capacity

Ringlock scaffolding outperforms many traditional scaffolding systems in terms of load capacity. For instance:

- A three-tier ringlock scaffold tower at a height of 6.3 meters can support 396.3 KN with 3mm steel.

- Larger diameter ringlock standards (OD 60.3mm) can bear up to 639.1 KN.

These figures make it ideal for heavy-duty applications like shoring and industrial infrastructure projects.

4. No Extra Couplers Required

Each ringlock component has built-in locks and fixed connection points. This eliminates the need for additional couplers or clamps, reducing:

- Loose parts.

- Assembly complexity.

5. Reduced Labor Requirements

The intuitive design of ringlock scaffolding minimizes the need for a large workforce. Components such as vertical standards with fixed locks enable quick installation and dismantling, often with fewer scaffolders.

6. Fewer Accessories

Compared to other systems like cuplock and kwikstage scaffolding, ringlock scaffolding requires fewer accessories:

- Ringlock Standards: Single ring at every 500mm interval.

- Cuplock Standards: Two cups (top and bottom) at every 500mm interval.

- Kwikstage Standards: Four V-clips per interval.

This simplicity not only reduces costs but also simplifies inventory management.

7. Lightweight Design

Ringlock scaffolding components are lighter than cuplock and kwikstage alternatives, making them easier to handle and transport. For instance:

- 1.0m Ringlock Standard: 5.39 kg.

- 1.0m Cuplock Standard: 5.81 kg.

- 1.0m Kwikstage Standard: 6.30 kg.

8. Longevity

Ringlock scaffolding is hot-dip galvanized, offering a lifespan of 15–20 years without rust. This durability ensures:

- Consistent performance across multiple projects.

- Lower maintenance costs compared to painted alternatives.

9. Efficient Transportation and Storage

Ringlock scaffolding components are stackable and can be packed in pallets or racks. This setup allows:

- Easy handling with forklifts.

- Space-saving storage in warehouses.

- Streamlined logistics for long-distance shipping.

10. Minimal Maintenance

Made from high-strength steel or aluminum, ringlock components are resistant to deformation and rust. This durability reduces the need for frequent repairs, further lowering operational costs.

Material and Dimensions

Material Options

- Steel: Hot-dip galvanized steel grades S235 and S355.

- Aluminum: Lightweight 6082-grade aluminum.

Standard Sizes

- Standards (Verticals): From 0.5m to 4.0m.

- Ledgers (Horizontals):

- Europe: 0.73m to 3.07m.

- USA: 2’2” to 10’.

- Planks:

- Europe: 0.73m to 3.07m.

- USA: 0.65m to 3.05m.

Diameter Options

- Standards: OD 48.3mm or OD 60.3mm.

- Ledgers and Transoms: OD 48.3mm.

- Diagonal Braces: OD 48.3mm or OD 42.7mm.

- Base Jacks: OD 38mm or OD 48mm.

Custom sizes are available to meet specific project requirements.

Why Choose Ringlock Scaffolding?

Ringlock scaffolding offers a comprehensive solution for modern construction challenges. Its advantages include:

- Time and labor efficiency.

- High load capacity for demanding projects.

- Durable materials with long service life.

- Reduced costs due to fewer accessories and maintenance needs.

With its versatility and robust performance, ringlock scaffolding is an excellent long-term investment for contractors and construction firms.

For more details on ringlock scaffolding and to explore customization options, contact us today!

What is a Modular Scaffold?

By definition, modular scaffolds are scaffolds that use prefabricated components that are specifically engineered and designed for whatever purpose they may serve. Its counterpart, tubular scaffolding, is the category in which the components are flexible and may actually be used for other purposes.

Moreover, modular scaffolding makes use of the latching mechanism, making it faster and more accurate to erect and establish, compared to other types of scaffolding.

Tubular vs Modular Scaffolding

Just because they’re not the same, doesn’t mean they’re different in all angles. There are quite a few similarities that modular and tubular scaffolding share.

Both of them use tubes as points of connection in building the scaffolding structure. In addition, they also have equally the same careful, strict, and thorough inspection and calculations in projects to avoid mishaps.

When it comes to their differences, it’s a bit more complicated than that. Here’s a table you can check out if you’re looking to get more information about how modular and tubular scaffolds are different:

Modular Scaffolding | Tubular Scaffolding | |

Flexibility | Modular scaffolding is flexible in a way that it can actually be used in different situations, but its components have specific uses. | Tubular scaffolding is flexible and versatile as it is. Its components can be used in different applications. |

Budget Needs/Requirements | Expensive but more secure and is actually more sought-after by construction businesses and organizations. | Cheap and inexpensive, but requires a lot of thinking and reconsideration to do. |

Timing | Fast and efficient. Erection and establishment can be done in hours. | Slow-paced. Requires a day or two to establish, depending on the height requirement. |

Safety | Excellent safety and security measures for both the erected structure and the workers who would man them. | Safe, but not as safe as modular scaffolding. Because of its versatility, it is prone to accidents. |

Applications | Can be used in the oil and gas industry, as well as engineering and architecture industries. | Can be used in the oil and gas industry, as well as engineering and architecture industries. |

These are among the differences between modular and tubular scaffolding. They’re not perfect as they both have their ups and downs, but operating and working on them properly can get you the output and results you’re looking for.

What are the Parts of a Ringlock Scaffolding?

The core of ringlock scaffolding structures are its parts. Without them, a ringlock scaffold wouldn’t be possible. There are a lot of parts and components involved, but there are a select few that are required in order to make sure that the structure will be erected on a standstill.

- Rosettes: These are the connectors that link the vertical and horizontal components for stability.

- Ledgers: On the other hand, ledgers are the horizontal support beams that give a surface for assembly.

- Standards: Standards are the building blocks of scaffolds. They’re the vertical members that offer height and strength to the scaffold.

- Diagonal Braces: The angled supports preventing wobbles and ensuring stability are called diagonal braces.

- Base Collars: Base collars serve as the anchors that make sure that the scaffold is steady and held tightly to the ground.

- Steel Planks: The surface platforms for workers. It’s where people walk and move within a scaffold, and the thing that’s offering a solid surface.

- Guardrails: The protective barriers along edges for safety from falling over the structure.

- Toe Boards: The low barrier components, preventing tools and materials from falling.

What is the Difference Between Ringlock and Cuplock Scaffolding?

From their terms alone, it would easy to figure out how different they are. While both fall under the modular scaffolding categories, these two scaffolding types are actually distinct and totally different from one another.

There are a few factors of consideration in identifying cuplock and ringlock scaffolding from one another. These are:

Aspect or Factor | Cuplock Scaffolding | Ringlock Scaffolding |

Speed of Assembly | Fast erection and assembly because of simple locking and unlocking systems. | Fast assembly made possible by minimal parts and component with snap-on designs. |

Components | Includes verticals, horizontals, diagonal braces, and steel planks. | Typically similar with cuplock scaffolding, just different when it came to rosettes. |

Connection Method | Uses a node and cup connection system | Uses rosette systems and ledgers. |

Flexibility and Versatility | Versatile and adaptable to structures. | Versatile and adaptable to structures. |

Strength and Durability | Good load-bearing capacity and strength. | Robust, strong, and sturdy. Perfect for heavy-duty construction. |

Applications | Typically for high-rise structures and other projects with similar risks. | Used in construction, maintenance, repairs, and some industrial projects. |

What is the Load Capacity of Ringlock Scaffolding?

The load capacity of ringlock scaffolding actually depends on the material used. As per several resources, light-duty scaffolding standards can support 25 pounds per square foot; medium-duty standards can go on for 50 pounds per square foot, while heavy-duty scaffolds are the strongest, supporting loads of up to 75 pounds per square foot.

Check this out to see the general guidelines of understanding capacity of ringlock scaffolds.

What is Bridge Scaffolding?

Bridge scaffolding, or also known as staging, is a temporary part of a scaffolding structure that’s used for the support work crew members, materials, and other things needed for the project.

They can be used for construction, renovation, as well as for maintenance and repairs of buildings, bridges, and other similar structures.

What is the Process of Ringlock Scaffolding Installation?

There are many different ways of ringlock scaffolding installation. However, we can give you the general step-by-step instructions on what needs to be done first.

Take note, though, that these might not be what all companies follow! They may be different, but this is just the general process on how they’re erected and installed.

Step #1: Position Base Plates

First things first – you want to make sure that the base is ready and is positioned correctly. Map your scaffolding structure out and fix the base plates properly.

Step #2: Affix the Jacks Onto the Bases

The next step is to insert the jack base onto the base plates. Doing so will allow you to start the insertion of standards in further steps. You can also adjust the base plate position if you find it necessary.

This step also entails the sleeving up of the base collars, protecting the base and allowing control on the base collar.

Step #3: Ledger Up Base Collars

When done, the next step would be to connect the two base collars using a ledger. Wedge and fit the ledger head onto the ring plate and ensure that the head is aligned with the mounting pole to avoid vertical misalignment.

Step #4: Add the Diagonal Brace

On a square, you’ll want to connect the two corners of the base collar ring plates using a horizontal diagonal brace, adding stability.

Step #5: Insert and Affix the Standards

Once the base collar has been secured, you can now insert the standards. Affix it with a pin and ensure that the end has a joint pointing upward.

Step #6: Add Layer Ledgers

When done, you’ll need to add another layer of the ledgers, creating the second level of your scaffolding structure. Repeat step 3 for this to create it successfully.

Step #7: Add the Vertical Diagonal Braces

The next step would be to ensure the integrity of the 2nd floor. So, vertical diagonal braces need to be added. It needs to form some type of “X” per layer.

Step #8: Secure the Second Layer

Then, you’ll want to secure the second layer. When done, you can go upward more and install the 3rd, 4th, 5th layers as needed, following steps 3 to 7.

Check this simplified video of how you can erect a ringlock scaffold system!

Why Rapid Scaffolding is the Best Option For Ringlock Scaffolding

For years, Rapid Scaffolding has dominated the entire market by providing top-of-the-line scaffolding structures to their clients. Our library of scaffolding options ranges from your typical ringlock scaffolding, cuplock scaffolding, to aluminum scaffolding, HAKY scaffolding, and many more!

Founded in 2003, Rapid Scaffolding was able to see through excellent levels of success through a juggle of clients globally. Offering 150 products in their line, they’ve completed over 2,500 projects and is not showing any signs of stopping.

Work With Us Today!

Being at the forefront of the scaffolding industry, we’ve seen it all. From the best and most advanced technologies and equipment to the most experienced and skilled employees, we got just what you need!

Reach out to our team today and we will go through your requests with you! We’ll send you a free quote for your project!

Contents

- Rapid Ringlock Scaffolding Video

- Why Rapid?

- 3D Model Of Ringlock Scaffolding

- Ringlock Scaffolding Components

- Ringlock Scaffold Specifications:

- Ringlock Standard

- Ringlock Ledger

- Ringlock Diagonal Brace

- Ringlock Bridge Ledger

- Ringlock Lattice Ggirder

- Ringlock Board Bracket

- Ringlock Base Collar

- Ringlock Caster Adapter

- Ringlock scaffolding is suitable for:

- Advantages of Ringlock Scaffolding

- 1. Saves Time in Assembly

- 2. High Versatility

- 3. Superior Load-Bearing Capacity

- 4. No Extra Couplers Required

- 5. Reduced Labor Requirements

- 6. Fewer Accessories

- 7. Lightweight Design

- 8. Longevity

- 9. Efficient Transportation and Storage

- 10. Minimal Maintenance

- Material and Dimensions

- Material Options

- Standard Sizes

- Diameter Options

- Why Choose Ringlock Scaffolding?

- Ringlock Scaffolding – The Ultimate FAQ Guide

- What is a Ringlock Scaffolding?

- Understanding What a Ringlock Is

- Advantages of Ringlock Scaffolding

- 1. Saves Time in Assembly

- 2. High Versatility

- 3. Superior Load-Bearing Capacity

- 4. No Extra Couplers Required

- 5. Reduced Labor Requirements

- 6. Fewer Accessories

- 7. Lightweight Design

- 8. Longevity

- 9. Efficient Transportation and Storage

- 10. Minimal Maintenance

- Material and Dimensions

- Material Options

- Standard Sizes

- Diameter Options

- Why Choose Ringlock Scaffolding?

- What is a Modular Scaffold?

- Tubular vs Modular Scaffolding

- What are the Parts of a Ringlock Scaffolding?

- What is the Difference Between Ringlock and Cuplock Scaffolding?

- What is the Load Capacity of Ringlock Scaffolding?

- What is Bridge Scaffolding?

- What is the Process of Ringlock Scaffolding Installation?

- Step #1: Position Base Plates

- Step #2: Affix the Jacks Onto the Bases

- Step #3: Ledger Up Base Collars

- Step #4: Add the Diagonal Brace

- Step #5: Insert and Affix the Standards

- Step #6: Add Layer Ledgers

- Step #7: Add the Vertical Diagonal Braces

- Step #8: Secure the Second Layer

- Why Rapid Scaffolding is the Best Option For Ringlock Scaffolding

- Work With Us Today!

- Get A Quote Now !