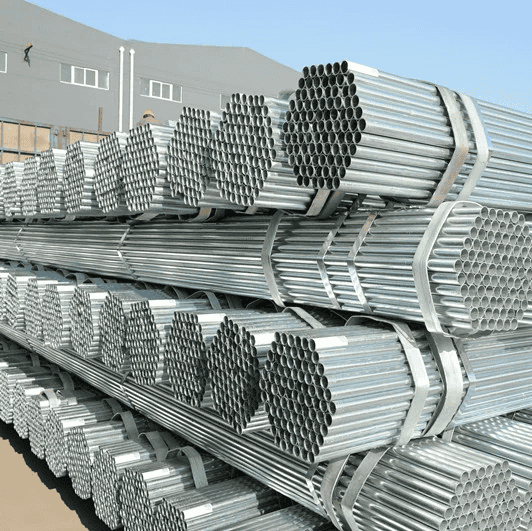

Scaffolding Pipe

Rapid Scaffolding is a reliable scaffolding pipe supplier from China. All types of scaffolding tubes are customizable in sizes, thickness and finishes to meet your basic needs.

Scaffolding Pipe Supplier

Scaffolding pipes are essential components used in construction to create a temporary structure that supports workers and materials while building or repairing structures. These pipes are typically made from steel, aluminum, or other robust materials to ensure stability and safety. The primary function of scaffolding pipes is to provide a safe and sturdy platform for workers to perform tasks at various heights.

Choosing us for your scaffolding needs means partnering with a reliable, experienced, and customer-focused provider. We are dedicated to delivering the highest quality products, unparalleled safety, and exceptional service to ensure the success of your construction projects. Contact us today to discuss your scaffolding requirements and experience the difference we can make.

Tube & Clamp Scaffolding

Tube and clamp scaffolding is a versatile and adaptable system that uses steel tubes and clamps (couplers) to create a sturdy structure. This system is highly flexible, allowing it to be configured in various shapes and sizes to fit complex construction requirements.

Scaffold Tube Specifications

- Tube Diameter: 48.3mm

- Thickness: 4mm or 3.2mm

- Steel Grade: Q235B or Q355B

- Length: 6m

- Surface Treatment: Hot dip galvanized

- Customization: Other sizes and materials available upon request

- Standard & Grade: GB 15831, EN 39, EN 10219, BS 1139, BS 1387-1985, JIS G 3444

Scaffolding Pipe Joints and Connectors

To create a secure scaffolding structure, various joints and connectors are used:

- Swivel Clamps: These allow pipes to be connected at any angle.

- Right Angle Clamps: Used to connect two pipes at a 90-degree angle.

- Sleeve Couplers: These connect two pipes end-to-end for extended lengths.

- other clamps

What is Scaffolding Pipe?

A scaffolding pipe is a fundamental element in traditional scaffolding systems used across various construction and maintenance projects. These pipes form the skeletal framework of the scaffolding, providing a stable and secure platform for workers to perform tasks at elevated heights. Made from robust materials like steel, aluminum, or galvanized steel, scaffolding pipes are designed to withstand significant loads and harsh environmental conditions.

Applications of Scaffolding Pipes

Scaffolding pipes are used across various industries and applications, including:

1. Construction Sites

- Building Construction: Scaffolding pipes provide safe working platforms for constructing buildings of all sizes.

- Renovation Projects: Used in renovation and restoration projects to access hard-to-reach areas.

2. Industrial Maintenance

- Oil and Gas Industry: Essential for maintenance and construction activities in refineries and petrochemical plants.

- LNG Offshore Scaffolding: Used for the maintenance of liquefied natural gas (LNG) facilities, ensuring safe access to various parts of the offshore platforms.

3. Infrastructure Projects

- Bridges and Dams: Provide support for construction and maintenance of large infrastructure projects.

- Road and Highway Projects: Used in the construction and repair of roadways and bridges.

4. Event Staging

- Concerts and Events: Scaffolding pipes are used to build stages, seating, and viewing platforms for events.

Advantages and Disadvantages Compared to System Scaffolding

Advantages of Scaffolding Pipes:

Flexibility and Versatility:

- Customization: Scaffolding pipes can be cut to any length and configured to fit various shapes and sizes, making them suitable for complex structures.

- Adaptability: Easily adapted to different site conditions and architectural requirements.

Cost-Effectiveness:

- Lower Initial Cost: Generally cheaper to purchase compared to some system scaffolding solutions.

- Availability: Widely available and can be sourced from numerous suppliers.

Simplicity:

- Basic Components: Consist of simple pipes and clamps, making them easy to understand and use.

- Minimal Training: Requires less specialized training to assemble and disassemble.

Disadvantages of Scaffolding Pipes:

Assembly Time:

- Labor-Intensive: Requires more time and labor to assemble and disassemble compared to modular system scaffolding.

- Complexity: Assembling intricate structures can be more complex and time-consuming.

Safety Concerns:

- Manual Assembly: The manual process can lead to inconsistencies and potential safety risks if not done correctly.

- Inspection Needs: Requires regular inspection to ensure all connections are secure and safe.

Weight and Handling:

- Heavier Components: Steel pipes can be heavy and cumbersome to handle and transport.

- Storage: Requires more space for storage when not in use.

Advantages of System Scaffolding:

Efficiency:

- Quick Assembly: Modular components are designed for quick and efficient assembly and disassembly.

- Standardized Components: Pre-fabricated components ensure consistent quality and safety.

Safety:

- Built-in Safety Features: Often includes integrated safety features such as guardrails and toe boards.

- Reduced Human Error: Standardized assembly reduces the risk of human error.

Load Capacity:

- Higher Load Limits: Typically engineered to handle higher loads and stress.

Disadvantages of System Scaffolding:

Cost:

- Higher Initial Investment: More expensive to purchase compared to traditional scaffolding pipes.

- Maintenance Costs: May require more maintenance and inspection over time.

Flexibility:

- Less Adaptable: Not as easily adaptable to irregular shapes and unique site conditions.

- Component Dependency: Dependent on specific system components, which may not be as readily available.

Conclusion

Scaffolding pipes are a versatile and cost-effective solution widely used in various industries, including construction, industrial maintenance, and event staging. While they offer significant flexibility and adaptability, they do require more time and labor to assemble compared to system scaffolding. System scaffolding, on the other hand, provides quicker assembly and enhanced safety features but comes at a higher cost and may be less adaptable to complex structures. Understanding the specific needs of your project will help determine the best scaffolding solution for your requirements.