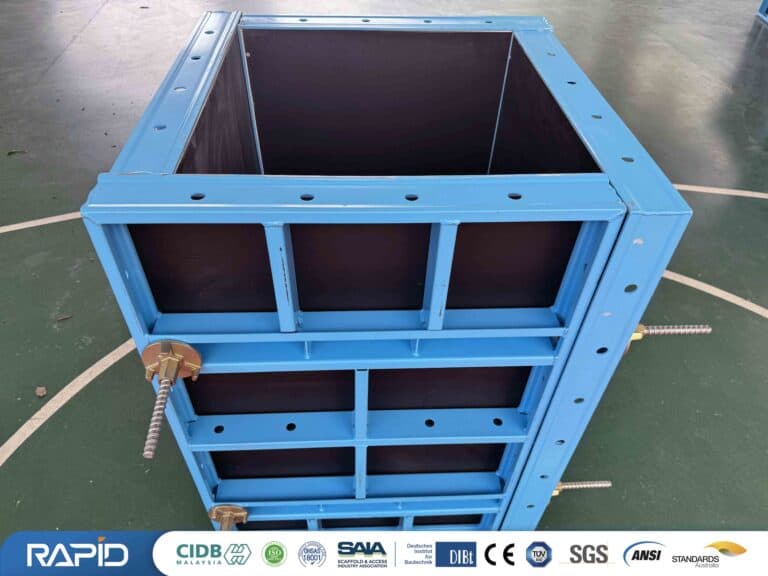

Steel Formwork

Single Side Formwork represents an innovative solution in construction, specifically engineered for scenarios where concrete pouring is limited to one side, often due to spatial constraints or the presence of existing structures. This method proves indispensable for projects like retaining walls and basement construction adjacent to established buildings, where traditional formwork is impractical.

Rapid Scaffolding specializes in Single Side Formwork systems designed for maximum durability and flexibility, capable of withstanding the lateral pressures of wet concrete through the use of advanced anchoring methods. These systems are tailored to facilitate smooth concrete finishes, ensuring efficiency and safety with a focus on reducing installation times and accommodating diverse project specifications.

Steel Formwork Project

Why Rapid?

•Versatility: Suits a broad range of projects, from high-rises to bridges. • Quality Finishes: Guarantees superior concrete surface quality.

• Auto-Climbing Technology: Offers safer, crane-less high-rise construction.

• Economic Efficiency: Balances cost-effectiveness with safety.

• Robust Load Capacity: Ensures reliability under high concrete pressures.

•Custom Solutions: Adapts to specific project needs with adjustable systems.

• Expert Support: Provides experienced guidance and service.

• Standards Compliance: Meets international safety and quality standards.

• Sustainability: Emphasizes reusable materials for less environmental impact.

Steel formwork, an essential component in modern construction, serves as a temporary or permanent mold into which concrete is poured to form structural elements of buildings. Unlike traditional wooden formwork, steel formwork is made from steel, offering enhanced durability, reusability, and strength. This guide dives into the essence of steel formwork, elucidating its materials, purposes, and why it’s indispensable in construction today.

What is Steel Formwork?

At its core, steel formwork comprises sturdy panels or frames crafted from steel. These panels are assembled on-site to create molds for concrete structures. The steel used is typically high-grade, engineered for its load-bearing capacity and ability to withstand the immense pressure of wet concrete. This formwork system is fundamental in constructing foundations, walls, columns, beams, and slabs.

Materials Used in Steel Formwork

Steel formwork is predominantly made from either stainless or galvanized steel. Stainless steel, known for its resistance to corrosion and extreme temperatures, ensures the longevity and reusability of formwork panels. Galvanized steel, treated with a protective zinc coating, offers additional durability against rust and environmental damage. These materials are selected for their strength, ensuring that the formwork can support the weight of concrete without bending or breaking.

Maximum concrete pressure 80kn/m2.

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Rapid represent the safety and qualified Steel Formwork via our construction projects.

Feel the Quality via our products. We improve them always.

Steel Formwork – The Ultimate FAQ Guide

Steel formwork is one of the most-sought-after formwork categories in the industry. Thanks to its relentless strength and overall resilience, it’s easily the favorite of many people, especially when they’re after durability and longevity.

Behind the shadows of steel formwork, however, there are a few important things that you need to consider before going with your decision of choosing steel formwork.

Contents

- Steel Formwork Project

- Why Rapid?

- Steel Formwork – The Ultimate FAQ Guide

- What is Steel Formwork?

- The 5 Types of Formwork

- Principles of a Good Formwork

- Is Steel Formwork Better Than Plywood Formwork?

- What are the 3 Stages of Formwork?

- How Strong is Steel Formwork?

- Pros of Steel Formwork

- Cons of Steel Formwork

- How to Choose Steel Formwork For Your Projects

- Is China a Good Place For Quality Steel Formwork?

- Rapid Scaffolding As Your Primary Steel Formwork Designer and Manufacturer

- Get A Quote Now !

What is Steel Formwork?

Steel formwork is a category of construction formwork that uses steel as its material-base. It’s an exceptionally-sought-after formwork because of the strength, sheer resilience, and heavy load-bearing capacity.

Overall, steel formwork is a construction tool/assistance that helps in molding and shaping concrete for floors, walls, and columns.

The 5 Types of Formwork

The construction industry has five different types and categories of formwork. These categories mainly discuss the material that’s used for the formwork.

Aluminum Formwork

It’s the type of formwork where 85% or more of the materials used are aluminum. It’s considered an excellent choice for long-distance projects and sites because they’re lightweight and can easily be transported.

Steel Formwork

Great for short-distance projects because they are heavy. However, they have excellent load-bearing capacities. Steel formwork mainly uses nuts, bolts, clamps, and locks to secure it.

Timber Formwork

This is probably the most common material or type of formwork available. It is also the oldest and the most-known type of formwork as it was used by a lot of construction businesses and companies worldwide.

Plywood Formwork

Plywood formwork is a type of formwork that’s made up of plywood sheets that are all piled together to form a mold. They’re man-made material, so, they can easily be sourced out. Plywood formwork is cheap, easy, and reliable, however, it’s drastically weak compared to timber.

Plastic Formwork

Last but most definitely not least is plastic formwork. From what it’s called alone, plastic formwork is the formwork type or category that uses plastic as its main material. It’s gaining traction and popularity because of the fact that plastic is an easy item to obtain, but is strong enough to hold weight. The main drawback here would be its environmental impact.

Principles of a Good Formwork

There are quite a few principles of what a good formwork is, and most of them is kind of self-explanatory. Most resources that are manned by civil engineers say that an excellent formwork would often have a few characteristics that make them “good,” these are:

- Must be strong enough to support both dead and live loads.

- Should be as light as possible.

- Must be capable of preserving its form when supported and braced horizontally and vertically.

- Should be built with sealed joints to avoid cement grout leaking.

- Should be capable of being removed in sections without causing damage to the concrete.

- Must be safe to reuse and repurpose.

- Must stand on a solid and stable foundation.

NOTE: These are just “good” characteristics to have on a formwork. Of course, there would still be other factors you should take into consideration, but these are the most important ones.

Here’s a video of the new Asia Aluminum formwork installation!

https://youtu.be/jJ6Ou44DLjY?si=82OuZxIbTYW3KdTZ

Is Steel Formwork Better Than Plywood Formwork?

To say that steel formwork is better than plywood is relative, because, there are certain instances and situations where plywood, or any wood of some sort is better than steel. However, if we’re talking about getting heavier-load bearing capacities, durability, longevity, and overall strength, steel formwork would absolutely take the lead.

The only downside of steel formwork is that it is quite expensive than plywood formwork. In addition to that, steel formwork also requires a higher skill level than plywood formwork.

What are the 3 Stages of Formwork?

Any formwork type can be divided into three separate stages: the building or erection, placement of the concrete, and the removal of the formwork. Let’s take a deep dive and discuss them each!

Step #1: Building or Erecting the Formwork

This step involves the assembly of the parts and components, aligning all of them, down to the bracing and the proper installation or erection process. It is the process where the building blocks of the formwork structure is prepared and built up.

Step #2: Pouring or Placement of the Concrete

The next step involves the careful pouring of the concrete to the formwork or the mold. Most, if not all construction companies often employ vibration methods, helping the concrete stay intact and compacted.

Step #3: Removal of the Formwork

Last, but most definitely not least is the removal of the formwork. When the concrete hardens, the formwork wouldn’t be of use any longer. So, the formwork will be removed from its place.

That’s the general overview of the three different stages of formwork. These apply to all formwork type, whether it’s made of timber, plywood, or even plastic.

https://youtu.be/YYVsIkziXrs?si=qKiqIU0FwXhxcvrX

How Strong is Steel Formwork?

It’s difficult to quantify the strength and overall rigidity of steel formwork. However, if we take it into perspective, steel formwork is a lot stronger and more robust than all other formwork types, making it the strongest of all.

It’s also extremely durable and rigid, making it the heaviest formwork type, too.

Civil Engineers say that steel formwork offers exceptional strength and durability, even though they’re permanent.

Pros of Steel Formwork

Steel formwork has its pros, and these pros are actually the reasons why many people choose them as their formwork type.

Fire Resistance

In a sense, steel formwork is extremely fire resistant. This adds an extra layer of protection to building sites and also contributes to the overall strength and resilience of the structure in high temperatures, as well as in the case of a fire.

Durability and Longevity

Steel formwork is extremely durable and long-lasting. They’re mostly capable of enduring heavy loads and hard building circumstances. Furthermore, they also have longer lifespans than other formwork materials and categories.

Reusability

In case you didn’t know, steel formwork is reusable. After every project, it can be cleaned and maintained, and still be used for other projects. Due to this, the costs for getting the formwork can be lessened.

Speed of Construction

Since most of the parts and components of steel formwork are already prefabricated, the construction time or speed of the is a lot faster and more urgent. This simply means that the operations will be able to start quicker, leading to lesser costs.

Flexibility and Versatility

Overall, steel formwork is highly-adaptable and compatible with a vast range of construction projects. These span from simple structures like single-story buildings to complicated structures that are dozens of feet high.

Accuracy and Precision

Last but most definitely not least is the excellent precision and accuracy that steel formwork exhibits. Its strong construction allows the formwork to have exact alignments and uniformities in concrete designs, which result in cleaner finishes and higher quality standards.

Cons of Steel Formwork

While steel formwork seems exceptional, there are a few things that should be reconsidered:

Heavy Weight

Steel is heavy, making steel formwork a heavy type of formwork. It’s steel formwork’s weapon to ensure that everything is kept stable and secure.

Possibility of Corroding

Since steel is not specialized to resist corrosion or oxidation, there’s a chance that the overall quality degrades over time. In order to prevent this from happening, special measures are needed.

High Cost

Steel formwork may have greater initial investment costs than other materials, affecting the budget, but long-term savings from reusability may compensate.

Limited Flexibility

Even if they’re robust, steel formworks may have limits in responding to unusual sites and projects. This can limit their availability and compatibility with certain project types.

How to Choose Steel Formwork For Your Projects

Being one of the most sought-after types of formwork for your project, it’s entirely essential to look for the steel formwork that you can consider a perfect fit for your projects. Among the most important considerations you should have in choosing a steel formwork are:

Weight

Steel formwork is heavy, but, you’ll be able to find manufacturers that provide lighter steel formworks than the others. Go for the one that is lighter but without compromising overall quality.

Reusability

It’s also important to note the reusability of a particular steel type. Galvanized steel is an excellent material that you can opt for if you’re looking for reusability.

Load Capacity

Of course, the more concrete there is, the heavier it will get. Ensure that the formwork of your choosing is capable of holding and handling the weight that’s needed. It’s concrete, so, it is extremely heavy.

Shape Retention

Lastly, how it retains the shape. Shape retention would be most often due to the way that steel has been put or installed. If you’re buying per part, ensure that the locks and clamps are connected to one another tightly and securely.

Is China a Good Place For Quality Steel Formwork?

Believe it or not, many countries all over the world go to China for most of their products. Besides the fact that Chinese manufacturers have the lowest and most menial price ranges in the market, they’re also known for the exceptional quality of products and services.

It’s a common misconception that Chinese brands only offer low-quality products and service because being in China alone and starting a manufacturing company is already a competition. There are a lot of high-quality steel formwork manufacturing and fabrication companies in the country, so the competition is tighter than ever.

From steel formwork to shoring frames, and even ringlock or cuplock scaffolding, you can bank and count on us!

Rapid Scaffolding As Your Primary Steel Formwork Designer and Manufacturer

For 20+, we here at Rapid Scaffolding have been on the forefront of formwork designing, innovation, and overall manufacturing and production of steel formwork. Our team takes pride in our overall capability and skillset not just in manufacturing formwork, but also in terms of choosing the material, as well as executing it.

Rapid Scaffolding has partnered up with globally-known brands and suppliers, providing them with nothing but excellent-quality components, knowledge, resources, and even customer support.

Wherever your business is in, and no matter how vast you think your business is, we here at Rapid Scaffolding are just a message or a call away. Reach out to us and get unrelenting support.

Contact us today and get high-quality steel formwork without worrying about the costs!