What Is the Importance of Formworks to Concrete Structures?

Wondering how to ensure durable concrete structures? Formworks provide essential support and shape during curing, ensuring stability, precision, and safety in construction projects of all sizes.

Formworks are crucial in concrete construction for shaping, supporting, and stabilizing wet concrete. They ensure accurate dimensions, enhance durability, and contribute to the safety and efficiency of construction projects.

Below, we explore the critical role of formworks in concrete structures, their benefits, and how they contribute to the quality and safety of modern construction.

What Are Formworks, and Why Are They Used in Concrete Structures?

Curious about formworks? These temporary molds are essential for shaping and supporting wet concrete, ensuring high-quality results in construction projects.

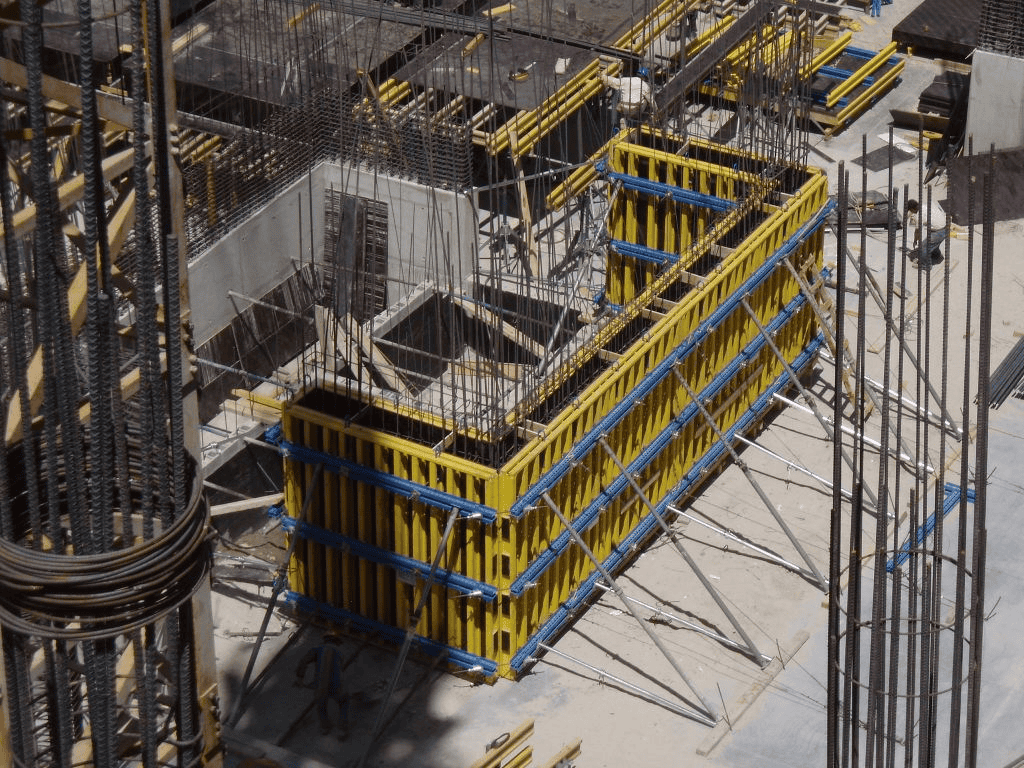

Formworks are temporary molds used to shape and support wet concrete during curing. They ensure structural stability, accurate dimensions, and high-quality finishes in concrete construction projects.

Formworks are temporary structures designed to hold and shape wet concrete until it hardens. Their purposes include:

- Shaping Concrete: Ensure accurate dimensions and alignment.

- Supporting Concrete: Prevent deformation and collapse during curing.

- Safety: Stabilize structures during construction.

- Quality Finish: Deliver smooth surfaces, reducing post-construction corrections.

Formworks are indispensable for creating durable, precise, and safe concrete structures.

What Is the Most Common Formwork for Concrete?

Wondering which formwork is the most widely used? Timber and plywood formworks are cost-effective and versatile, making them the preferred choice for many concrete construction projects.

Timber and plywood formworks are the most common types due to their affordability, ease of use, and adaptability for various structures. They are ideal for small to medium-scale projects.

The types of formwork commonly used for concrete include:

- Timber Formwork: Cost-effective and widely used for small projects, offering easy customization.

- Plywood Formwork: Provides smooth finishes and moderate reusability.

- Steel Formwork: Preferred for large-scale projects due to its durability and precision.

- Modular Systems: Increasingly popular for complex structures and repetitive tasks.

Timber and plywood remain the most accessible and flexible options, especially for projects with tight budgets.

How Do Formworks Enhance the Quality of Concrete Structures?

Want high-quality concrete structures? Formworks provide stability and precision, ensuring durability and minimizing defects in finished projects.

Formworks improve concrete quality by maintaining shape, ensuring even curing, and providing smooth surfaces. They prevent structural issues, ensuring long-lasting and aesthetically pleasing results.

Formworks enhance concrete quality in several ways:

- Maintaining Shape: Prevents bulging or uneven surfaces.

- Ensuring Proper Curing: Even curing improves strength and durability.

- Minimizing Defects: Reduces cracks and other flaws.

- Providing Smooth Finishes: Eliminates the need for extensive surface corrections.

By ensuring precision and stability, formworks significantly improve the overall quality of concrete structures.

What Are the Benefits of Using Formworks in Concrete Construction?

Looking for efficiency and safety in construction? Formworks offer numerous benefits, from reducing material waste to ensuring stability and durability in concrete structures.

Formworks enhance construction efficiency, reduce material waste, and improve safety. Their reusability and precision contribute to cost-effectiveness and high-quality concrete structures.

The benefits of using formworks include:

- Efficiency: Speeds up construction with prefabricated systems.

- Cost-Effectiveness: Reusable materials reduce long-term expenses.

- Safety: Stabilizes structures, preventing accidents.

- Durability: Ensures strong and stable concrete.

- Precision: Achieves accurate dimensions and smooth finishes.

Formworks are vital for safe, efficient, and high-quality construction projects.

How Do Formworks Contribute to the Safety of Construction Projects?

Concerned about construction safety? Properly installed formworks stabilize concrete, ensuring worker safety and reducing risks of collapse or structural failure during curing.

Formworks contribute to safety by stabilizing concrete during curing, preventing deformation, and protecting workers from potential hazards. Proper installation and maintenance are key to minimizing risks.

Formworks enhance construction safety in several ways:

- Structural Stability: Prevents collapse or deformation during curing.

- Worker Protection: Provides a stable platform for workers.

- Accident Prevention: Reduces risks of falling debris or structural failure.

- Compliance: Meets safety standards and regulations.

Proper use of formworks ensures safer construction sites and reliable concrete structures.

What Are the Environmental Benefits of Modern Formworks?

Interested in sustainable construction? Modern formworks minimize waste and improve efficiency, reducing the environmental impact of concrete construction projects.

Reusable formworks reduce material waste, promote resource efficiency, and lower environmental impact. Advanced systems made of steel or aluminium further enhance sustainability in modern construction.

Modern formworks contribute to environmental sustainability through:

- Reusability: Steel and modular systems reduce material consumption.

- Waste Reduction: Minimized debris from prefabricated designs.

- Energy Efficiency: Faster assembly reduces energy usage on-site.

- Durable Materials: Long-lasting materials lower overall resource demand.

Environmentally friendly practices in formwork design benefit both construction projects and the planet.

Conclusion

Formworks are essential in concrete construction, ensuring stability, precision, and quality while enhancing safety and sustainability. By understanding their importance, builders can achieve durable, efficient, and high-quality results.