What Is the Use of Formworks in Construction?

Struggling with efficient concrete casting? Formworks provide essential support for shaping and holding concrete structures during curing, ensuring quality, safety, and precision in modern construction projects.

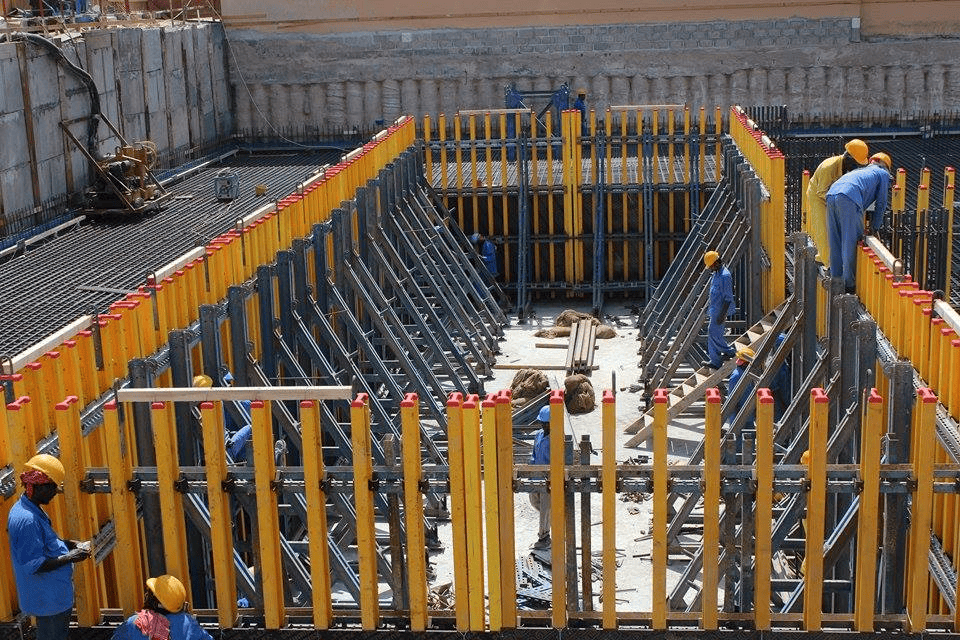

Formworks are temporary or permanent molds used in construction to support freshly poured concrete until it hardens. They ensure structural accuracy, enhance safety, and provide a framework for creating various shapes and sizes.

Below, we explore the functions, benefits, and types of formworks in construction, helping you understand their critical role in achieving high-quality, durable, and cost-effective building solutions.

What Is the Main Purpose of Formwork?

Wondering why formworks are essential? They serve as molds to shape and support concrete structures during curing, ensuring structural integrity and enabling a seamless construction process.

The main purpose of formwork is to hold and shape freshly poured concrete until it hardens. It provides structural stability and ensures the desired design and dimensions are achieved.

The main purpose of formwork is to act as a temporary or permanent mold for holding freshly poured concrete. It supports the concrete until it gains sufficient strength to bear its own weight and withstand applied loads. Formwork ensures that the structure takes the correct shape, size, and alignment as specified in the design. It also helps maintain safety during construction by stabilizing the concrete and preventing spillage or deformation. Proper use of formwork leads to high-quality finishes, reducing the need for additional corrective work.

What Is the Essential Function of Formwork in Building and Constructing Houses?

Building a house? Formwork ensures accurate dimensions, smooth finishes, and structural stability, playing a vital role in the construction of walls, columns, beams, and slabs.

Formwork is essential for constructing houses, providing molds for walls, slabs, and columns. It ensures safety, precision, and high-quality finishes, enabling the seamless execution of building designs.

In residential construction, formwork is indispensable for shaping and supporting concrete structures. Its key functions include:

- Shaping Structural Elements: Provides precise molds for walls, columns, beams, and slabs, ensuring they meet design specifications.

- Ensuring Safety: Stabilizes concrete during curing, preventing collapse or deformation.

- Enhancing Aesthetics: Offers smooth finishes that reduce the need for plastering or additional work.

- Speeding Construction: Facilitates quick assembly and disassembly, saving time and labor.

Whether building a single-family home or a multi-unit complex, formwork ensures the safety and quality of the final structure.

What is the role of formworks in modern construction?

Curious about formworks’ importance today? They play a critical role in enabling innovative designs, sustainable practices, and efficient construction, shaping the future of urban and industrial development.

In modern construction, formworks support architectural innovation, ensure sustainable practices, and facilitate complex designs. Their adaptability and efficiency contribute to advancements in urban and industrial infrastructure.

Formworks are indispensable in modern construction, serving multiple roles:

- Architectural Innovation: Support intricate and complex designs that are otherwise difficult to achieve.

- Sustainability: Enable efficient use of materials and reduce environmental impact through reusability.

- Speed: Accelerate project timelines by facilitating quick and accurate concrete casting.

- Versatility: Adapt to various construction needs, from small residential projects to large-scale industrial developments.

Formworks continue to evolve with technology, supporting the growing demand for sustainable and efficient construction solutions.

What Are the Types of Formworks Used in Construction?

Unsure which formwork suits your project? Various types, such as timber, aluminium, and steel, cater to specific construction needs, ensuring efficiency and durability in concrete casting.

Common types of formworks include timber, steel, aluminium, and plastic. Each type offers unique advantages, catering to different project requirements, from cost-effectiveness to durability and reusability.

There are several types of formworks, each suited to specific construction needs:

- Timber Formwork: Traditional and cost-effective, but less durable and suitable for small-scale projects.

- Steel Formwork: Durable and reusable, ideal for repetitive tasks and large-scale projects.

- Aluminium Formwork: Lightweight and corrosion-resistant, perfect for high-precision structures.

- Plastic Formwork: Lightweight and easy to assemble, often used for modular construction.

- Plywood Formwork: Versatile and cost-effective, commonly paired with timber for added durability.

Choosing the right formwork depends on project size, budget, and specific structural requirements.

What Are the Benefits of Using Formworks in Construction?

Want a seamless construction process? Formworks enhance efficiency, safety, and precision, ensuring high-quality results while reducing labor, material waste, and construction timelines.

Formworks ensure accurate shaping, reduce construction time, and minimize material waste. Their reusability makes them cost-effective, while their stability improves safety and quality in concrete structures.

Formworks offer several key benefits in construction:

- Precision: Ensure concrete structures meet design specifications, improving accuracy and reducing errors.

- Safety: Provide stability during the curing process, protecting workers and the structure.

- Efficiency: Speed up construction timelines by offering reliable molds for concrete pouring.

- Cost-effectiveness: Reusable formworks, such as aluminium or steel, reduce material costs over multiple uses.

- Waste Reduction: Minimize material waste by controlling concrete placement and spillage.

These advantages make formworks an integral part of modern construction projects.

What Are the Challenges Associated with Formworks in Construction?

Facing difficulties with formworks? Common challenges include high initial costs, labor requirements, and maintenance needs, which can affect construction timelines and budgets without proper planning.

Challenges with formworks include high costs, potential for damage, and labor-intensive assembly. Proper planning and handling are essential to maximize efficiency and minimize disruptions during construction.

While formworks are crucial, they come with challenges:

- Cost: High-quality formworks, like aluminium or steel, have significant upfront costs.

- Labor Requirements: Skilled labor is often needed for assembly, disassembly, and maintenance.

- Damage Risks: Poor handling can result in dents, cracks, or reduced usability.

- Storage: Formworks require adequate storage space to prevent damage during downtime.

Addressing these challenges through proper planning and training ensures that formworks deliver their full value in construction projects.

Conclusion

Formworks are vital in construction, offering support, precision, and efficiency in concrete casting. By understanding their types, benefits, and challenges, builders can optimize their use, ensuring high-quality and sustainable construction outcomes.